CNC Turning

The most common device used in the industry is the metal CNC machine, which is used in various industries such as jewelry and automobile manufacturing. But it has been proven that these devices are effective in more modern and complex industries such as medical and computer industries. Sepyani Industrial Group with skilled and experienced experts will make and implement CNC machine for you.

What is CNC lathe and how does it work?

In a brief definition, it can be said as follows: CNC lathes have a function similar to manual and traditional lathes, with the important difference that they will increase the utilization, precision and quality by using numerical control. Numerical controllers deal with various technologies and devices. One of these devices is CNC lathes, which are used to make a large collection of parts. These models of devices are controlled and programmed by an interface to the computer.

Considering the advancement of technologies, CNC lathes are replacing old traditional machines very quickly. This model of devices has many advantages. The following are among the advantages of these modern devices:

- Simple organization and management

- Highly repeatable with proper accuracy

instruction:

Planning and execution of various routines by CNC machine is mainly done by CAD and CAM software. In this way, the programmer will design the program manually by the said software and then upload it to the CNC control. After performing some other arrangements, such as obtaining the zero point of the tool and part, the operation of the machine will be done automatically. The CNC lathe is controlled by an interface to the index on a computer.

The operator who runs the program will be able to watch the way the machine works in every stage of production through simulation. Due to the existence of this technology, the user will no longer need to know the details of the machine he is working with compared to the similar situation in traditional machines.

Note: For those workshops and factories that have a lot of demand for production and accuracy and repeatability are considered as their pillars, CNC lathe is a worthy choice. Also, the use of appropriate tool stocks (turret) and the ability to use pre-planned programs and obtain production and process patrols make the operator less concerned, and therefore, working with several CNC machines at the same time becomes possible for one operator. Compared to traditional machines, it is considered a great transformation in terms of production and productivity.

8 Components of Lathe Machine:

- Gearbox: It is a local device in which the spindle and the main engine are used and it performs the transfer of work. In situations where high torque is needed.

- Belt: for high revs with lower torque

- Bed: the part where the tart moves on the rail. These rails are hardened in such a way that the performance and friction of the parts will not have an effective erosion effect on it.

- Chuck

- Bird: It is usually used due to its greater effect on the protection of the workpiece to the spindle. In cases where the length of the piece is long, a chicken should be used.

- Pedals: It is used for hydraulic control and restraint of three systems and the bird shaft.

- Control panel: It is the brain and core of analyzing and performing the work of the machine. From this point you will have control over the device.

- Tart: tools for turning, milling, drilling, etc. will be installed on the tart and it is necessary to index them on the base.

Note: the driving force in the tarts has different models based on the need: electric, hydraulic or using a servo motor.

Different models of tarts:

VDI model: In this model, the speed of changing tools and setting up tools and holders is faster.

BMT model: The installation speed of the holder will be much lower but with more power.

The main skills required to work with a CNC lathe:

- Mastering graphics software such as Corel Draw and 3D Max

- Accuracy in choosing the right drill

Advantages of using CNC machines:

- It has the ability to control with a modern and smart software that will control and control the car very well.

- It will reduce human intervention to the minimum possible and prevent human errors.

- It increases the production speed and the manufactured parts will not need to be edited.

- They will make the construction flow more economical from an economic point of view.

- It is dedicated to work on various materials and will be able to strengthen our scope of activity.

- Increasing the level of security and reducing the operations required by the operator

- Increasing efficiency and making the most of production

- Reducing production time and increasing process speed

- Excellent quality

- Excellent repeatability

- Flexibility in production

- Ability to find errors and correct them

- No need for frequent operator inspection

- The ability to save various designs in the car’s memory and use them again

Different models of CNC

Different models of CNC and its different functions in different industries:

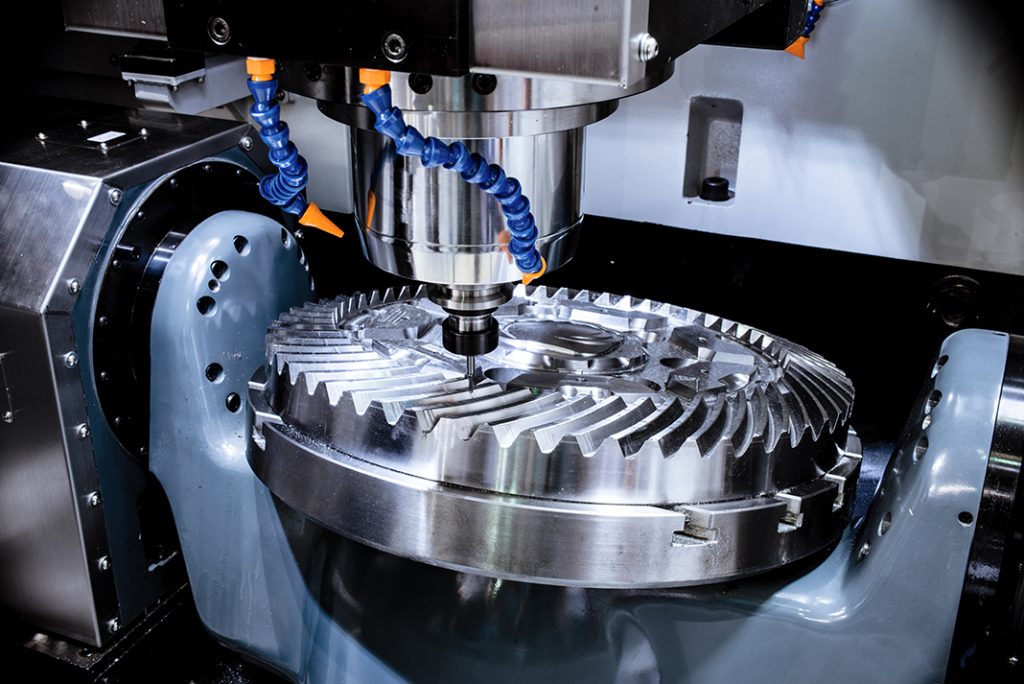

Metal CNC machine

These machines are designed in a unique way to work on ferrous and non-ferrous metals and are among the most desirable and efficient CNC machines in the industry.

From the manufacture of parts in the automotive industry to the manufacture and production of jewelry and decorative ornaments, there are examples of the uses of metal CNC machines in the industry. Currently, a large number of ordinary turning workshops in the city use these machines and it is one of the most basic tools and tools for their income.

Wood CNC machine

This model of machines is used for cutting wood and MDF. Considering that the essential and important part of the furniture industry is done with the efficiency of CNC wood machines, these machines are at a good level from the point of view of use, and there is a possibility of their efficiency in large and small workshops.

This machine is used to produce equipment such as computer desks, chairs, decorative frames, wooden decorative items, furniture inlays, making wooden sculptures, etc.

Stone CNC machine

Tombstone making workshops and statue making workshops have allocated the most and most important efficiency of these machines. However, at present, the stone-cutting and stone-cutting workshops of the construction industry will be able to use these devices for the purpose of engraving on stone and preparing epitaphs, which are mainly popular from an artistic point of view.

In fact, stone CNC machine is effective in the field of interior decoration in buildings and also for works such as inscriptions, stone sculptures, tombstones, etc.

Glass CNC machine

The production of decorative parts in the automotive industry, as well as the production of mirrors and glasses for building facades, are considered the most basic functions of these machines.

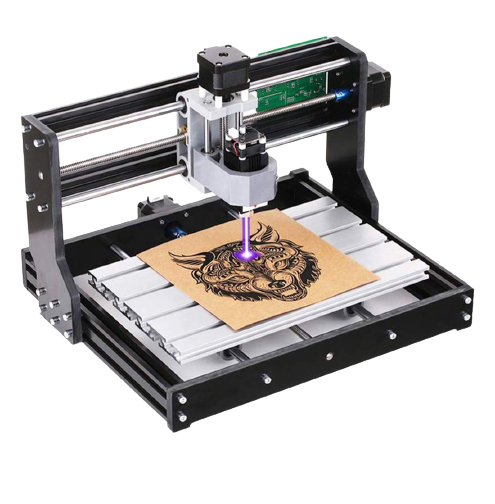

CNC laser machine

Laser is one of the most powerful cutting tools that can be used to work on various materials. The CNC laser machine is actually the same common machine that uses laser rays for its cutting tool.

This special feature has made it possible for the industry to produce extremely precise and sensitive parts such as computer parts and medical equipment. However, it is possible to allocate lasers for various materials such as stone, metal, and glass, which is effective in selecting a machine.

Machine (CNC) dotting, engraving and flat cutting

This machine is only used for carving and inlaying on wood, stone, glass, etc. and cannot be used for cutting other materials; Because it is designed in such a way that by removing a part of the work, it creates a two or three-dimensional design.

Wirecut machine (CNC)

This machine engraves the plan and map on the work piece by using electric sparks. This machine works by discharging the current between two electrodes and eventually parts of the work piece will be removed.

When the distance between the electrodes decreases, the electric field intensifies and becomes stronger than the conductor. This process causes pieces of the workpiece to be removed by each of the electrodes.

Waterjet cutting CNC machine

It is a tool that cuts hard materials such as granite and metal with high water pressure. In some of these tools, water is mixed with sand or any powerful abrasive material that results in a thicker work. Parts of factory devices are mostly produced by this process.

The waterjet machine is generally used to cut materials that do not have the ability to withstand high temperatures of other devices. For example, this machine is used in the aerospace and mining industries. The waterjet machine is effective for mechanisms that require complex cuts; Because the low temperature of the machine prevents any change in the desired material.

CNC milling machine

The CNC milling machine is executed in the way of programs that consist of commands based on numbers and letters and will guide the parts at different distances. The programs that will be used for the milling machine will be able to be based on G-code and the programming language designed by the production group.

CNC lathe machine

In a CNC lathe, parts are cut with tools that can be divided in circular directions. Lathe cuts with CNC technology are done with more accuracy and speed. This machine is used to make complex designs that cannot be done with manual machines. The control and control methods of CNC milling and turning machines are similar.

Various uses of CNC machines:

- automobile manufacturing

- Oil industry segmentation

- Cars and weapons

- Wood and carving

- Laser cutting machines

- Engraving machines

- Gold and jewelry making

The most famous brands of CNC machine manufacturers:

- KDT

- Excitech

- Biesse

- Siemens

- Unitech

- Sinumerik

- Fanuc

- Num

- Heidenhain

- Hust

- GSk

How the CNC machine works:

A programmer will be able to manually design a part or parts of the mold production path, and then the encrypted computer file will be loaded into the CNC machine, and the machine will automatically produce the desired tools for which the design has been done. In the machining and molding industry, the CNC lathe has grown dramatically, especially in the design and operation of CNC lathes, we have observed a remarkable growth.

CNC lathes, like other CNC lathes, have become an important part of the construction industry in recent years. As a result, we expect that the performance of these devices will continue to improve in this field.

Conclusion:

The experts and consultants of Sepyani Industrial Group will be with you from the first step of decision-making to the productivity of CNC machines. The engineers and technicians of the Sepyani team, chosen from among the best, will always try to satisfy our dear customers by providing the best services and quality at the most appropriate price. For more information, you can contact us through WhatsApp or other communication methods.