WINCC

WinCC software is one of the products of the German Siemens brand, which is used for industrial monitoring. In fact, industrial monitoring includes depicting the process and creating graphic images to communicate with the process and operator of the control system of a factory or an industrial unit.

Wincc software will allow the user to monitor the main processing. And if needed, be able to change the parameters applied to the equipment. wincc software has the ability to connect to all PLCs and controllers that support OPC. One of the most important features of wincc software is its data logger, which is the most efficient part of monitoring software in all processes.

What is Industrial Automation?

This software is called an HMI software or system. HMI or Human Machine Interface is actually an interface between man and machine. Using this software, it is possible to set alarms or warnings that will sound automatically when certain events occur in the project. At the same time, while working with the wincc software, you can take a printout of the processed or unprocessed data or save the data on your computer for documentation purposes.

Sepyani Industrial Group with a brilliant history in the field of designing and setting up industrial automation, Siemens industrial automation and plc industrial automation is grateful to you for accompanying us to the end of this article in order to learn more about wincc software. To better understand the mentioned introduction, let’s take a quick look at the meaning of some terms:

PLC:

PLC or in other words Programmable Logic Controller which is also called Programmable Controller. An industrial digital computer is designed and manufactured to control industrial processes, such as assembly lines, robotic equipment and any activity that requires high reliability control. Ease of programming and simple troubleshooting of the process is one of the characteristics of PLC.

In other words, plc is a software controller that receives data in binary form in the input section and processes them according to the program stored in its memory. And the result of this operation will also be sent from the output section in the form of commands to receivers and actuators. In other words, PLC is considered a logical controller for which it is possible to define the control logic by a program. And in case of need, it can be easily changed.

Monitoring:

Monitoring is a practice related to observing or displaying the conditions of a system. In general, the definition and concept of monitoring can be described as follows:

Collecting required data from various parts of industrial units (separate and non-separate) and presenting them in special formats on the monitor in front of the responsible operator.

But this way of naming and working is incredibly old because now monitoring has a broader definition than just displaying status. For example, nowadays it is possible to give commands to operators through monitoring systems. Or establish two-way communication with some parts. Entrust the design and implementation of industrial automation in your factory or production line to the engineers and experts of Sepyani Industrial Group. Benefit from our free consultation service by completing the consultation request form. Sepyani Industrial Group will always be by your side from consulting to personnel training and after sales services.

HMI:

HMI is short for Human Machine Interface and means the interface between man and machine. It is used to monitor and adjust the parameters of industrial systems such as PLC, inverter, etc. HMI is actually a programmable LCD monitor. And also, with its support, it will be possible to plan various parameters and control mechanisms.

HMIs are segmented in several ways. The way of working with them is considered to be one of those that can be set in 2 touch modes (Touch HMI) and Text Panel (Text Panel). Although its touch model is better known as TOUCH PANEL. It is both more professional and more expensive, and it is used in easier cases in the TEXT PANEL type. And although its cheapness is also involved in this choice.

Difference between HMI and WinCC:

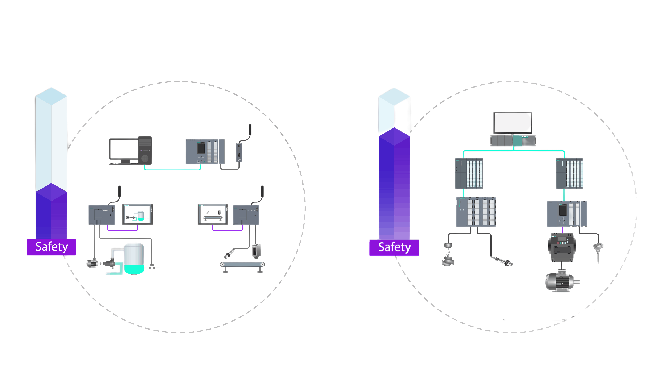

The word HMI actually stands for Human Machine Interface, which means the interface between machine and human. WinCC software is considered a type of HMI. And there is no difference between them. However, HMIs are implemented in several ways:

- Software

- Hardware

Main parts of WinCC software

wincc software consists of 7 main parts or bases, each of these bases has special duties. And by each one, it is possible to perform certain operations.

wincc explorer:

The central part of the Wincc software is the wincc explorer. In this section, various project categories and their management can be seen. In order to build and design various parts of a monitoring system, special editors are provided in this environment, each of them will form a sub-system.

- The graphic part

- Warning section

- Measurement and processing part

- Reporting section

- Communication section

- Part of standard interfaces

- The price of software interfaces

The graphic department or graphic designer:

It is an editor that is used to create images. In this editor, it is possible to place all graphic objects through which a complex process is created.

Tags:

A tag is used to limit PLC addresses. In each wincc project, each tag has a unique name, and after creating that tag, you can also create a label that connects that tag to the PLC. Usually, two types of tags are used in wincc software.

- Internal tag

- External tag

In the internal type, the tags will not have any connection with the PLC and are considered exclusively memory positions in the program. But external tags are connected to PLC. It is possible to define these tags in order to categorize and simplify in separate groups. It is possible to access all tags through the tag logging window. In fact, tags are stored in this section. By accessing this window, you will be able to access all the tags in the software in a short period of time and correct or delete them if needed.

Text library editor:

The text library editor is used to add different languages to the project. In this way, various words are written under the title of the desired language. And their meanings in other languages will be defined in front of it.

Editor report designer:

The report designer editor is also used to create layouts and print reports.

Cross reference:

Through the cross reference section, it is possible to find different places where a tag is used and edit them if needed.

User archive:

By using the user archive section, we can save all the process information on our computer or send it to the PLC.

Global script:

With global script, we will be able to write programs in both C and Visual Basic languages and make dynamic graphic objects using them.

Administrator user:

By user administrator or admin window, it is possible to define different accesses for different users.

Redundancy:

Redundancy section is an extremely used and very important section. With it, we will be able to determine if one of the computers is disconnected for any reason. The other computer stores all the user’s messages, processes and archives.

Horn:

Horn editor is a section where you can define your desired song. And then for every special event that happens, this song will be played.

Application of WinCC HMI monitoring software:

- Presenting the status of all machines and devices in real time

- The ability to register and present the required and important components of the system

- The ability to warn when an error occurs in the system

- Display the exact location and time of the error

- Having graphic tools suitable for existing processes

- Recording necessary and required data such as production rate, performance rate, amount of energy consumed, etc.

- Remote control capability to view systems status

- The possibility of adjusting the system with the desired process

Features of a suitable hardware for monitoring system:

- Ability to make communication cables between PC, HMI and PLC

- The possibility of editing graphic pages and setting the parameters of each part

- The ability to download programs from software to hardware

- Ability to synchronize HMI with PLC system

Types of WinCC:

- WinCC Scada

- WinCC TIA Portal

- WinCC Flexible

- WinCC Unified will give authorized operators the ability to access the core system through current web browsers without the need to install standalone plugins.

WinCC Scada

WinCC software makes it easy to generate and build web pages on the SIMATIC S7-1500 server in the TIA Portal. In other words, SIMATIC WinCC is a Supervisory Control and Data Acquisition (SCADA) and Human Machine Interface (HMI) system developed by Siemens.

SCADA systems are used to monitor and control the physical processes involved in industries and infrastructures in large scale and long distances. It is possible to use SIMATIC WinCC in combination with Siemens controllers. It is necessary to remember that WinCC is also designed to be installed and run on the Microsoft Windows operating system.

In 2010, WinCC and PCS 7 were the first SCADA systems to be attacked by malware. One of those attacks was done by the Stuxnet virus. This virus is able to collect data from infected systems and even reprogram them.

WinCC TIA Portal

WinCC (Portal TIA) is software for use in all HMI applications. From the easiest operational solutions with simple panels to SCADA applications in multi user computer based systems. SIMATIC WinCC engineering software (TIA Portal) is offered in WinCC Basic, WinCC Comfort, WinCC Advanced and WinCC Professional versions. WinCC Advanced and WinCC Professional are also available as stand-alone Runtime software packages, which can be expanded with productivity options.

This software contains innovative tools to configure all SIMATIC HMI operator panels. These devices also have WinCC Runtime Software, which is available as a separate and independent product for PC (Windows) platforms.

Installation and commissioning of WINCC software

In a situation where Siemens PCS7 software is installed on a system. Siemens WINCC software will be installed automatically. In this case, the user does not need to install the software again. But if the Siemens STEP7 software is installed alone on the system. You have to independently prepare WINCC software and install it.

Different types of Industrial Automation

Conclusion:

Wincc is a software designed for use in automation technology. Its main efficiency is in the fields of factory process control by using full graphical capabilities and forms. Overall, the goal of industrial automation is to relieve technicians and employees from risky jobs. At the same time, improve quality by eliminating human errors and reducing costs. Which will result in better productivity, security, quality and increase. Now the question may be raised for the managers of factories and production workshops, how are they able to adapt the set under their supervision to industrial automation?

With Sepyani Industrial Group, in addition to importing the desired equipment from famous brands, especially the Siemens brand, and gathering the best experts and elite Iranian engineers, it has provided services such as design, installation and commissioning of industrial automation, Siemens industrial automation, plc industrial automation.

We at Sepyani Industrial Group will be with you, and help you with industrial automation setup required for the desired collection. It is enough to define your project using one of our communication methods and entrust the implementation of automation in your collection to the capable hands of Sepyani Industrial Group’s elite engineers and experts. Contact us through WhatsApp for more information.