Types of Hydraulic Linear Cylinders

A hydraulic linear cylinder is a tool that converts fluid power into mechanical power in a linear way. It is also called a hydraulic jack. This tool is used to intensify a small force in order to create a larger force. Mechanically, this device has a function very similar to a pulley. with the difference that the hydraulic jack uses an external power source. This tool, which is used in many industries to move heavy objects, is classified in various forms and types.

What is a hydraulic cylinder?

It is a tool that converts the stored force in hydraulic fluids into a force in a linear path and is mostly used to produce linear motion and force. In many chemical industries, it is used to make tools and connect and compress by establishing a connection between the device and hydraulic control. One of the useful features of this type of cylinder is that they will work in very hot and very cold temperatures without any problems. Therefore, it is of great importance in many productions and industries. In fact, in order to maintain, move and move in the hydraulic industry, hydraulic linear cylinders are used.

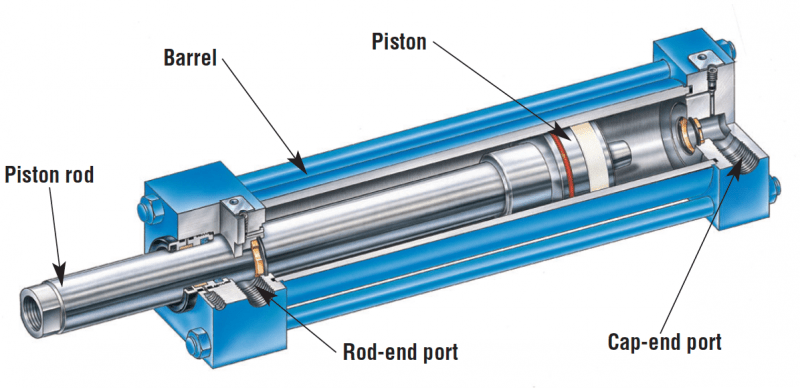

Mechanism of linear hydraulic cylinder

The hydraulic system of this device consists of a hydraulic motor and one or more cylinders along with a pump. In fact the pump uses the power from the engine to flow the oil, and then the hydraulic cylinders use it to create pressure to produce linear movement. The hydraulic jack in this device works based on Pascal’s principle. When the jack pump is activated, pressure is applied to the hydraulic fluid in the cylinder and it completely surrounds the one-way valve in the device.

The hydraulic linear cylinder has two separate cylinders, one of which is bigger. When force enters the liquid, it will create pressure in the entire volume and surface of the cylinder. Therefore, applying a force to the small cylinder causes a much stronger force than the larger cylinder.

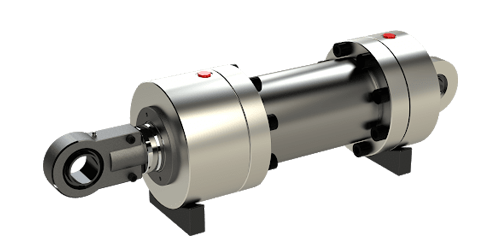

Hydraulic linear cylinder structure

The components of this device include:

- Cylinder

- Cylinder bottom

- Cylinder bottom connections

- Pump

- Hydraulic motor

- Cylinder head and its connections

- Piston

- Piston rod

- Cylinder body installation base

It is also useful to know that in some types, the bottom of the cylinder is welded to the body. And this issue causes damage to the inner part of the body. Therefore, the more appropriate way is to screw these two parts together. In this case, even the maintenance costs of this equipment will be low.

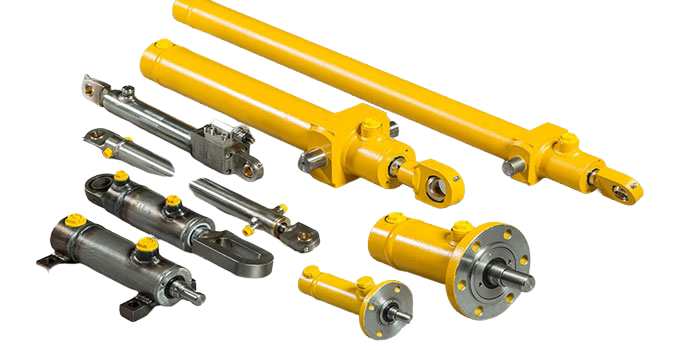

Types of linear hydraulic cylinders:

Hydraulic cylinders are divided into two ways. Division based on the performance of cylinders and another division based on their characteristics.

In the classification based on the performance of this device, the hydraulic jack is divided into two different groups. While 4 different groups can be distinguished based on their characteristics.

Types of linear hydraulic cylinders based on the type of function:

1- one-way hydraulic cylinders

In this type of fluid, it is pressurized from only one side. Also, to return the piston to the previous position with the help of a spring, the required force is applied on the other side of the cylinder. Of course, an external force can be used instead of a spring. Due to structural problems in most springs, it is not recommended to use this type for long-term use.

2- Two-way hydraulic cylinder

As its name suggests, pressure is applied to the fluid from two directions. In this type, one-way and two-way piston shafts are used. The piston rod is located on both sides of the cylinder.

Types of hydraulic linear cylinders based on features:

1- Plunger hydraulic cylinder

This type, which is also called ram cylinder, is generally placed vertically, this way of placement causes the fluid supply to the cylinder to be stopped and returned to its original state by the weight of the shaft and piston. Basically this type is used in car repair shops.

2- Telescopic hydraulic cylinders

The type of linear hydraulic cylinder is also called multi-stage. This type can be used in situations where space is limited. The number of steps in them sometimes reaches 6 steps. There are one-way and two-way types of this type. Also, they have a high course, and for this reason, they are used in the construction of forklifts and cranes.

3- Cable hydraulic cylinders

These types of cylinders are able to work with both hydraulic and pneumatic systems. These cylinders are only two-way. They have a high course. It is recommended to use this type in situations where space is limited.

4- Diaphragm hydraulic cylinders

This type of linear hydraulic cylinder is produced in two forms: flat and round edge diaphragm. Diaphragm type around the piston will not have any leakage.

Applications of hydraulic linear cylinders

This device is used in many applications and industries. There are many applications of this equipment and it is also very important.

Steel industries:

They are used to create linear movements in machines and equipment used in the steel industry. Hydraulic cylinders are considered to be very important equipment in large places. High power, high efficiency, good efficiency and high precision, easy maintenance and repair, and lastly, accurate and non-deviant movements have made it widely used.

Chemical industry:

These types of cylinders are resistant to corrosion and decomposition. This feature has caused it to have many applications in the chemical industry. The high reliability factor and the ability to withstand high pressures are other features of this equipment.

Mining industries:

In this department, hydraulic linear cylinders are used to make many large machines and devices. The reason for this is the high speed and high pressure resistance of this device. In the mining industry, hydraulic jacks are used in drilling machines and crushers, as well as mill equipment.

Agricultural industries:

Clump breakers and threshers are among the machines of the agricultural sector, in which these hydraulic equipment are used. In fact, hydraulic jacks are used for transmission in most of the machines in this sector.

Automotive industry:

The creation of form and shaping in the special sheets of the car body is done by this hydraulic system. They also use the hydraulic system in the brake and steering section of the car. Hydraulic presses are able to shape the car body at high weights and very high pressure.

Industrial devices:

In order to transmit power and speed, hydraulic linear cylinders are used in various industries. In fact, most industrial devices have used these devices. Because their speed and power are both precise and controllable.

Sepyani Industrial Group is a leader in providing and selling industrial equipment and machinery needed by industries, ready to provide equipment needed by respected manufacturers. Other services of this experienced group include the following:

1- Industrial automation

2- Industrial automation plc

3- Equipment related to industrial electricity

4- Consulting and setting up the production line

5- Services related to the repair and maintenance of industrial machinery

To receive services in any of the above lines, you can contact the experienced consultants and engineers of Sepyani Industrial Group.

Advantages of hydraulic linear cylinder:

- Compared to other equipment with the same performance, they require less space and this is considered an important advantage.

- They are effective and efficient for moving very heavy loads.

- No need to make a lot of effort to increase the load

- It is very easy to use.

- It has less weight than other types.

Disadvantages of hydraulic linear cylinder:

- Increasing the possibility of breaking the hydraulic jack in case of oil wear

- They are almost slow.

- Due to the use of hydraulic oils in an overheated state, the device has an unpleasant smell.

- It heats up almost quickly.

How to calculate pressure?

The pressure in this system is obtained by dividing the unit of pressure by the unit of area. In fact, when the piston moves outward, it is calculated as the force on the surface, and when it moves inward, it is calculated as the force on the surface difference between the piston and the piston shaft.

Hydraulic linear cylinder speed

The two factors of the cross-section of the cylinder and the piston rod with the input oil flow rate affect the speed of this equipment. If we consider the inlet flow to be the same, the speed can be calculated using the following equation:

V=q/a

In the above relationship, the speed of the piston is specified by v, the oil flow rate is specified by q, and the cross-sectional area of the piston is specified by a. The return movement time in the cylinder is faster than its departure time. The reason is the lower volume in the piston rod.

What factors should be considered when buying a hydraulic jack?

It is recommended to pay attention to the following points before buying this equipment and then prepare it.

- Cylinder diameter

- Cylinder stroke length

Conclusion:

The hydraulic linear cylinder is one of the most widely used equipment in various industries in order to carry out large and heavy movements. Different types of it have been designed and marketed for different applications. These cylinders, which work with the help of hydraulic power, have many advantages. Accuracy and high level of reliability on one hand and high ability to withstand high pressure on the other hand have added to the efficiency of this product. For more information contact us through What’sApp.