Pneumatics

In general Pneumatics and pneumatic equipment is that part of engineering and physics that uses the energy contained in compressed gases to move and do work. Pneumatics plays an important role in the science of mechatronics and the construction of various devices in various industries.

It is through pneumatic force that pneumatic valves convert the energy obtained from compressed gases into movement and mechanical energy. Of course, it should be noted that pneumatic actuators often supply their required power from electric compressors.

In this article, we are trying to learn more about pneumatic parts and equipment, as well as related accessories. If you are interested in this topic, you can refer to the article titled “What is pneumatics?” See also advantages and disadvantages.

What is pneumatics?

As mentioned, pneumatics is a branch of physics that creates mechanical force and movement by means of compressed gases, especially air. Pneumatic systems have components and accessories to achieve the intended performance. One of the pneumatic equipment is the air compressor. Another part that is used in pneumatic systems are cylinders. It is the movement of the cylinders that provides the necessary power to move the engine. The next important part in a pneumatic system is the actuator. This part of the pneumatic equipment makes the valves open or close when necessary. Engines are also considered as one of the main and very important components in this system.

Pneumatic accessories and fittings

Pneumatic systems include a wide group of connections and accessories such as couplings, valves and adapters. Of course, these connections are also connected to other devices that receive power. For example, pneumatic tools and equipment can include any type of connectors that are designed to connect different components and parts of the device in dry air or under pressure. Pneumatic systems and its connections and equipment are used in various sectors of various industries. These applications include:

- Assembly and commissioning of production lines

- Industrial Machinery

- Hand tools

- Construction

The reason for the many applications of pneumatic systems is that the power produced in this method is very reliable, safe and economical. It is also equivalent to the power that electric motors are capable of producing.

All types of pneumatic fittings and equipment:

Although the connections and equipment related to the pneumatic system include a wide range. But here we will introduce some of its types.

Elbow joints

Pneumatic elbow joints are used to connect individual hoses or multi-purpose hoses. These connections allow users to change existing connections for a group of pipes. Another feature of elbow joints used in pneumatic systems is that they are very suitable for nylon pipes and are versatile and do not get stuck.

Pneumatic direct connections:

This part of the pneumatic equipment has threads on one side and is suitable for connecting to the pipe on the other side. These connectors are used to connect a bunch of hoses. Also, pneumatic equipment is mostly used as an adapter. In terms of diameter, size, material and grade, these types of pneumatic connections have a wide variety. In the following, you can see other features of these components:

- High safety

- Usability for a wide group of tools

Pneumatic Y connections:

The applications of this type of pneumatic connections are mostly used in airlines and air tools, robotics and garages, as well as automobiles. The main features and characteristics of this part of pneumatic equipment include the following:

- Tight connections

- Having a tank resistant to flow and also vacuum

- Easy connection end that can be used even with one hand.

Pneumatic T connections:

This part of the pneumatic equipment has a pressure mechanism. They also have a secure connection to threaded ports. Tee fittings are threaded from one end. And for this reason, they are very easy to install. So that it is possible to install them without having special tools and with only one hand. In cases of vacuum or pressure, pneumatic connections are used. The following are the main features of this type of connection:

• Perfect hole design

• Very little leakage

Functional pneumatic connections:

These connections allow their users to be used in whatever function they need in the appropriate role. The material of this group of pneumatic equipment is mostly aluminum alloy, brass and copper. Among the basic and important features of these connections, the following can be mentioned:

- High variety

- Having various functions from flow regulation and blocking to supply and shutdown

Other classifications of pneumatic fittings:

There is another type of classification related to pneumatic components and connections, which is named according to the type and style of assembly. The most common types of these connections and pneumatic equipment include items such as the following:

Pneumatic compression fittings:

In addition to having greater safety and reliability, this type of connection is also easy and quick to assemble or disassemble. This part of pneumatic equipment is usually made of metal or plastic. The plastic material of these connections is used for systems where the pressure is low. This is while its metal types are used in conditions where the temperature of the system is higher.

Pneumatic pipe-to-pipe connections:

This type of connection is available in the market in a wide variety of diameters, materials, and sizes. In order to connect two pipes together, pneumatic fittings and equipment are used. These types of connections are available in all types of straight drug angles. When working with materials such as polyurethane, nylon or polyamides, they use this type of connections.

String connections to pneumatic pipe:

This type of pneumatic fittings and equipment consists of male and female parts. These pneumatic connections are used in situations where sealants and coatings are exposed to contamination and corrosion.

Pneumatic barbed fittings:

These pneumatic equipment are actually pressure fittings. The method of use is that it is pressed from the upper part of the pipe and then it is fixed around the pipe with the help of a bent nut. This connection method also has high safety.

Prominent brands in the field of pneumatic fittings and equipment production:

Today, many manufacturers and large companies are producing and supplying these pneumatic equipment to the market. In this section, we will only introduce some of these well-known brands.

- Festo brand

- Brand Parker

- Norgen brand

- RS Pro brand

With years of experience in the field of importing and selling tools such as pneumatic fittings and equipment, Sepyani Industrial Group is a safe and ideal platform for supplying the parts you need. Sepyani Industrial Group also provides services in the field of PLC industrial automation and consulting and setting up production lines as well as implementation of production lines.

What parts are pneumatic fittings and equipment connected to?

Pneumatic equipment can be connected to a wide group of devices and ducts. Especially the hoses and pipes that are connected to the air in different parts of the system. Which pneumatic connections and equipment is the best option for your user also depends a lot on the amount of pressure in the operations that will be performed.

But the important point is to pay attention to the ducts that hold compressed air on both sides of the connections when choosing pneumatic fittings and equipment. Then, according to the amount of pressure in this area, you will choose the best option. These components include things like the following:

Pipe

If a tube is used in the pneumatic system. It indicates the presence of substances that are closer to the solid state. They are a better option for permanent and long-term installations. Pipe connections in pneumatic equipment are generally fixed more firmly than other types. However, sometimes they are designed and used for frequent separations. Pipes are made and bought and sold according to their diameter.

hose

The use of hose in pneumatic systems indicates the presence of flexible ducts. Hoses are made of one or more layers of plastic material. The possibility of tear and wear in the hoses is high, and for this reason they should be replaced at regular intervals. For this reason, hoses are used in connections and pneumatic equipment that are not permanent and can be easily separated after a while.

What are the consumable parts in the pneumatic system?

Pneumatic accessories and equipment are sometimes of a consumable type, in this section we refer to this part of pneumatic equipment:

Air pump or compressor:

They have the same application as gas capsules, except that instead of methane gas, there is air in pneumatic compressors.

Pneumatic care section:

This section of pneumatic equipment is used to optimize the air. This part consists of three parts:

- Pneumatic filter

- Pneumatic regulator

- Pneumatic oil

Hose and pneumatic connections:

Hoses are considered as the main components and parts in the pneumatic system. This section connects all parts of the system and other pneumatic equipment.

Pneumatic actuator:

The actuator in the pneumatic system converts the energy in the compressed air into movement. This movement can be circular or even linear.

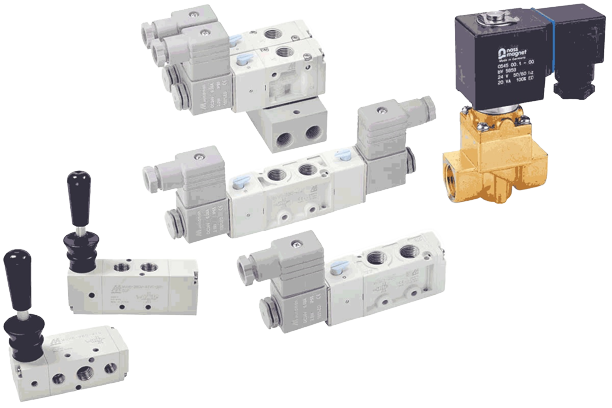

Pneumatic valve: This part of pneumatic equipment is used to control cylinders and jacks. This section itself consists of various components:

- electric valve

- hand valve

- Pneumatic signal valve

- Pneumatic flow control

- Pneumatic pedal

Air gun in pneumatic system:

This device is used to transfer air. Inflating parts and other pneumatic equipment the process is done through this part.

Pneumatic cylinder or jack:

This part of the pneumatic equipment produces mechanical power. The movement of cylinders in a pneumatic system is generally rotary or reciprocating. These jacks are used for tasks such as moving parts and compressing them.

Conclusion:

Considering the many applications that pneumatics and pneumatic systems have in many industries and uses. Knowledge of pneumatic accessories and equipment is helpful for getting to know more about this topic. When choosing and buying any pneumatic equipment, you should pay attention to the usage and the pressure that should be borne. In the meantime, in order to make the best choice in this field, it can be very helpful to get advice from those who have good experience and expertise in this regard. For more information contact us by What’sApp.