Cooling Tower

Cooling Tower has long been used to cool chillers and similar items in the industry. In many cases, this equipment is called a cooling tower. Of course, their modern types have undergone many changes. In fact, advances in science and technology have also affected the structure of these coolers. And the technologies used in them have improved. For example, fiberglass is used in the body of cooling towers. And this has led to an increase in the life of this equipment. In the following, we will learn more about the structure and function of cooling towers.

Different Types of Pasteurizers

What is a cooling tower?

A cooling tower is a device that receives the temperature and heat generated in cooling air conditioning systems or industrial equipment and then transfers it to the atmosphere. This very important device in industries is grouped into two distinct types.

Different types of cooling towers:

In order to categorize these cooling equipment, the method of operation has been set as a criterion. Based on this, they are divided into two main groups:

- Open circuit type

- Closed circuit type

In the following, we will fully introduce each of these types of coolers.

1- Open circuit cooling tower:

This type, which is also known by other names such as wet and evaporative cooling, has a very high cooling efficiency. The reason for this name is that the hot water that is pumped to the cooling tower for cooling flows in an open area in the tower. In this passage, it comes into contact with the outside air. And due to contact of hot water with open air, part of it turns into steam. For this reason, this type of cooling tower is also called evaporative or wet.

On the other hand, due to the evaporation of a part of the hot water in the process of passing through the cooling tower, this amount of lost water must be replaced by injecting water. Therefore, we use water in this type of cooler. The hot water in the chiller or any other similar industrial equipment is sprayed from the top of the tower to a part called packing. In this part, air and hot water are in close proximity. The heat and temperature of hot water will be transferred to the air in this way.

What parts does the open circuit cooling tower include?

- Electric motor: centrifugal type or its axial model and cooling fan

- Packings: in order to reduce the speed of water and increase the contact surface of hot water with air

- Pan: or a basin where cooled water collects in the lower part of the tower.

- Drip catcher: This section is located between the packing and the fan and is required to prevent water particles from leaving the upper part of the tower.

- Hot water distribution system: This part is made of nozzles and water spraying pipes.

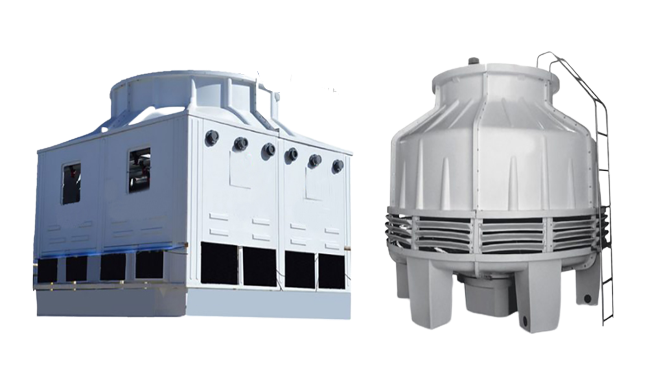

- In terms of physical structure, open circuit cooling towers consist of two types: round and cubic. The materials used in their construction are fiberglass and galvanized.

2- Closed circuit cooling tower:

This type of cooling tower is also known by other names such as dry and cooler. This type is called closed circuit. Because the hot water cools in a completely closed circuit and is not in contact with the open air and gives its temperature to the atmosphere. For this reason, no part of the hot water evaporates.

Therefore, there will be no water consumption in this type of cooling towers. So, naturally, water injection is not done either. Hot water or any hot conflicting fluid that flows in the pipes transfers its heat to the air with the help of a fan. In fact, the walls of the pipe are heated and this heat is transferred to the outside environment.

What are the parts of a closed circuit cooling tower?

These types of coolers are made up of different sections and parts according to their function and structure. Like:

- Inlet: water or any other hot fluid enters the pipes through this way.

- Coil: This section is actually a number of bent and finned tubes.

- Fan: It is a means of transferring heat from the body of the pipes to the outside.

- Air inlet: In this section, outside air is brought in for use in the cooling process.

- Water outlet: from this part, any fluid that was hot at the beginning of entering the cooling tower is cooled.

In fact, because there is no contact between the air and the contents inside the pipes. And the path is completely closed in closed circuit cooling towers. Therefore, instead of water, any other fluid can be cooled in this way, and this is considered a great advantage for this type of cooling towers.

3- Hybrid cooling tower:

This type of cooling tower is actually a combination of the previous two types. Hot water flows inside the coils. Also, the air flow is established vertically on the pipes from the bottom to the top. On the other hand, water is sprayed on the surface of the pipes from the upper part of the tower.

Sprayed water particles turn into steam in contact with the hot surface of the pipes. In this way, the temperature of the hot water inside the cooling tower pipes is cooled. Air flows around the coils. And this air flow makes the hot water cooling process faster. It is also possible to stop spraying water on the surface of the pipes in cold seasons. In this type, no fan is used. Because the surface of the pipes is sprinkled with water.

Sepyani Industrial Group, one of the most successful groups in the field of industrial equipment and industrial automation, has produced and marketed various types of cooling towers. To get this equipment and other equipment you need, it is enough to choose one of the communication methods through the “Contact Us” page and contact us. Cooling towers have other divisions based on the method and arrangement of air flow.

Types of cooling towers based on the flow method

1- Cooling with uneven flow:

In this type of cooling towers, air flow and direction and water flow used for the cooling process are created and established in opposite directions. In this way, water is supplied by nozzles that are connected to the collector in the upper part of the tower. It is sprayed from the top to the bottom and the air is blown in the opposite direction from the bottom with the top of the tower.

2- Cross flow cooling:

The required air flow in this type of tower is blown horizontally from the side parts of the tower. The water used is also entered vertically by nozzles from the top of the tower. Therefore, air flow and water flow are actually perpendicular to each other. In this way, the air used for cooling will have less contact with hot water. For this reason, in terms of work efficiency, this type is at a lower level than the asymmetric current type.

Cooling Tower applications in industries:

These equipment have very wide applications in all kinds of industries. Industries that use cooling towers include:

- Oil industry and refinery

- Petrochemical Industries

- Thermal power plants

- Nuclear power plants

- Chemical factories

- Food industry

- Casting

- Induction furnaces

- Rubber industry

- Toli glass industry

- The automotive industry

- Dairy factories

Of course, its uses are not limited to these. In the following, we will discuss the applications of these cooling towers in more important industries.

Application of Cooling Tower in power plants:

Cooling towers are needed to cool the heat coming out of the turbines. After being converted into saturated steam, the hot water moves to the turbines. These turbines are connected to the generator. And they are forced to move by the kinetic energy in the saturated steam. At this stage, the cooling tower comes into action and turns the saturated steam into saturated water.

Application of cooling tower in oil refineries:

In refineries, crude oil is heated to 400 degrees Celsius. And then in the distillation towers step by step and with the help of cool water they are divided into oil fractions. In this process, cooling towers are used to lower the temperature of the converters.

Application of cooling tower in rubber industry:

In the rubber production line, there is a machine called plastic injection. This device includes injection and molding parts. At the beginning of the work, small plastic particles are placed in the funnel. Then they are directed into the cylinder and pushed towards it through circular movements.

Elements are embedded in the outer part of these cylinders. These elements are thermal. Next, solid plastic turns into liquid plastic. And it is made from the desired parts. Finally, it is necessary to cool the plastic injection machine with the help of cooling towers.

Factors affecting the capacity of cooling towers:

When preparing and buying cooling towers, their capacity should be considered. This issue is very important in the efficiency of cooling towers. Important factors and parameters affecting the capacity of these towers include:

- Fluid used for cooling

- Temperature and dry heat as well as relative humidity in the place of installation of the tower

- Flow rate of circulating water

- The temperature and heat level of the water entering the cooling tower

- The temperature and amount of heat required for the water leaving the cooling tower.

Common problems in cooling towers:

Sometimes, the performance and efficiency of the cooling tower face problems. Or even the amount of energy used in the cooling tower increases significantly. These cases indicate defects in the cooling tower. The problems and defects of cooling towers include:

- Leakage in the tower

- Formation of deposits in the cooling tower

- Dust in the tower

- Microorganism contamination in different parts of the tower

- The presence of vibrations and a lot of noise

Sepyani Industrial Group is proud to announce that in addition to supplying all types of cooling towers with the best quality, it also undertakes services related to the maintenance and repair of these equipment. The brilliant expertise and experience of Sepyani engineers and technicians will guarantee the quality of the work. Other Sepyani Group services include PLC Industrial Automation. Also, consulting and setting up the production line is also done by the consultants of this group.

Conclusion:

Cooling Tower is one of the most widely used equipment in various industries. These cooling towers have different types and capacities. The best way to make an ideal choice is to consult with experts and engineers in this field. For more information, you can complete the consultation request form so that we can contact you as soon as possible. You can also contact us through WhatsApp.