What is a flow meter?

A flowmeter is an integral tool for measuring the flow of liquid, gas or a mixture of both in applications used in the food and beverage industry, oil and gas plants, and chemical/pharmaceutical plants. Different types of flowmeters are available in the market with fluid characteristics (single phase or two phase, viscosity, turbidity, etc.) and flow characteristics (laminar, transitional, or turbulent, etc.).

Flow meter applications:

Flow range and the need for accurate measurements are key factors in determining the right flowmeter for a particular application. Additional considerations such as mechanical limitations and output connection options also affect this choice. The overall accuracy of a flowmeter depends in part on the application conditions. Pressure, temperature, fluid and dynamic effects can potentially alter the measurement taken.

How the flow meter works:

Industrial flowmeters are used in environments where noise and sources of high voltage fluctuations are high. This means that the analog front-end (AFE) must operate at high common-mode voltages and have very good noise performance. In addition to processing small electrical signals with high accuracy and repeatability, the 4 to 20 mA loop is the most common interface between current transmitters and current control equipment such as programmable logic controllers. Current transmitters can be fed from this loop or have a dedicated feed line.

How current transmitters work:

Current transmitters designed for loop use have very strict power limits. As all electronic devices need to receive/process and transmit signals to operate only from the 4-20mA loop. Ultra-low-power processors such as the Texas Instruments MSP430 and TMS320C5000 DSP families are commonly used in loop transmitters in conjunction with high-precision, low-power AFE solutions. Transmitters with digital connectivity features such as PROFIBUS, I/O links or wireless connectivity are increasingly popular. Because it reduces setup time, continuous monitoring and error detection. All these factors greatly improve the productivity and efficiency of the automation loop.

This article reviews the performance of four of the most common flowmeters: differential pressure, electromagnetic (magmeter), Coriolis, and ultrasonic, the last of which includes Doppler displacement and transit time flowmeters. Key applications of these flowmeters are presented along with their advantages/disadvantages and system considerations.

Differential-pressure flow meter:

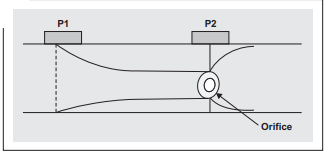

This flowmeter works based on Bernoulli’s principle. It measures the differential pressure drop across a blockage in the flow path to obtain the flow velocity. Common types of differential pressure flowmeters are:

- Orifice, pitot tube and venturi tube

- Orifice flow meter is used to create blockage in the flow path. As the fluid flows through the hole in the orifice plate, according to the law of conservation of mass, the velocity of the fluid leaving the orifice is greater than the velocity of the fluid approaching the orifice.

- According to Bernoulli’s principle, this means that the pressure is higher on the inlet side. Relative to the pressure on the outlet side, measuring this differential pressure gives a direct measurement of the flow rate, from which the volume flow can easily be calculated.

System considerations for differential pressure flowmeters:

- Advanced technology with easy maintenance and no moving parts

- Suitable for turbulent flow

- Poor accuracy for measuring low currents

- It uses the extractive current measurement technique. So there is always a permanent pressure drop that has to be overcome with additional pumping energy.

- The need for accurate placement of pipe fittings, elbows and bends for downstream and upstream compression valves.

Electromagnetic current meter (magmeter):

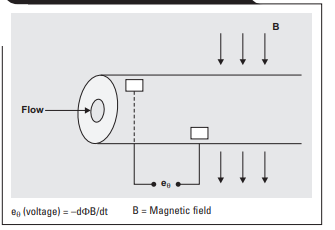

Electromagnetic flowmeter, also known as magnetism, works based on Faraday’s law of electromagnetism and can be used to measure the flow of conductive fluids only. Two field coil magnets are used to create a strong magnetic field across a tube. According to Faraday’s law, when liquid flows through the tube, a small electric voltage is induced. This voltage is received by two sensor electrodes located throughout the pipe. The fluid flow rate is directly proportional to the amplitude of the induced electric voltage.

The coils used to create the magnetic field can be powered by AC or DC power sources. With an AC source the coils are fed with a 50 Hz AC signal. This has the advantage that it draws less current from the system than the DC source method. However, the AC excitation method is susceptible to interference from adjacent power cables and line transformers. Additionally, null drift is a common problem with AC systems and cannot be calibrated.

System considerations for electromagnetic flowmeters (magmeters):

- It can only measure fluids with conductivity greater than 10 µS/cm, it is not possible to use them in petroleum, oil and gas industries because the conductivity of hydrocarbons is poor.

- The choice of sensor-electrode varies depending on the direction, pipe construction and type of fluid installation.

- No loss in system pressure where it may be critical.

- Applications that cannot withstand pressure drop such as low flow applications

- Ideal for corrosive and dirty fluids, slurry, etc., provided that the liquid phase has sufficient conductivity because the flowmeter has no internal parts.

- High accuracy up to ±1% of indicated current

- Higher cost

Coriolis flow meter:

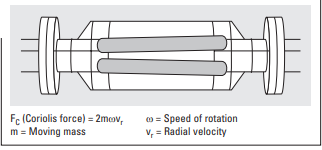

This popular flowmeter directly measures mass flow. Shown as a straight pipe or as a double curved pipe. It is easier to build and maintain with a straight pipe because it is under lower pressures. But it is susceptible to interference and noise. With dual curved tubes, it cancels out any incoming noise as the two tubes oscillate in opposite phase.

The oscillating movement of the tubes is superimposed on the linear movement of the fluid and exerts torsional forces on the tubes. This twist is caused by the Coriolis acceleration, which acts in opposite directions on both sides of the pipes, and the resistance of the fluid to vertical movement. The sensor electrodes, which are placed on both sides of the input and output, receive the time difference caused by this movement. This phase change due to torsional forces is a direct measurement of mass flow rate. The figure below shows the diagnosis results.

System considerations for Coriolis flowmeters:

- Direct measurement eliminates the effects of temperature, pressure and flow characteristics on mass flow measurement.

- It has high accuracy.

- The sensor can measure current simultaneously.

- Velocity and density depend on the density of the flowing fluid due to the basis of the oscillating frequency of the tube(s).

- It is not possible to measure fluid flow with particle bubbles (liquid with gas or solid particles; gas with liquid bubbles, etc.) because such particles reduce humidity. Fluctuations in the tube make it difficult to measure accurately.

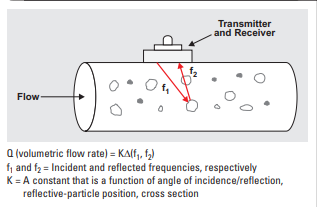

Ultrasonic flow meter Doppler-shift meter:

As its name suggests, it works based on the Doppler effect. This meter consists of sensors of transmission and reception nodes. The node transmits a 0.5 to 10 MHz ultrasound wave into the fluid moving at a velocity v. Fluid particles or bubbles are moving simultaneously. By changing the frequency, the difference in frequency between the transmitted and received ultrasound waves is the measurement of flow velocity. Because this type of ultrasound flowmeter needs sufficient reflection. Particles in a very pure liquid do not work in single-phase fluids.

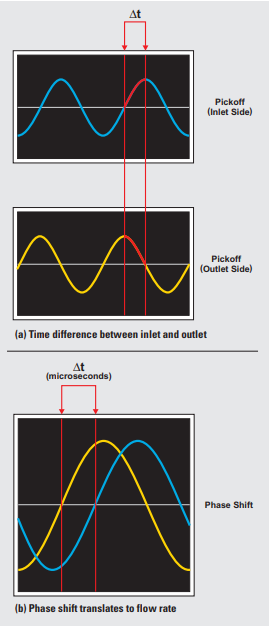

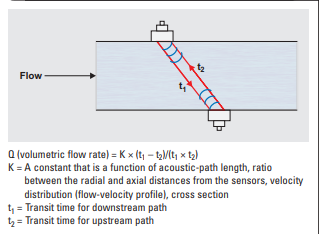

Transit-time meter:

In contrast, time-lapse ultrasonic meters are only used to measure very clean liquids or gases. It consists of a pair of ultrasound transducers mounted along an axis at an angle to the fluid flow axis. These converters, each consisting of a transmitter/receiver pair, transmit to each other alternately. The flow of fluid through the pipe creates a difference between the passage times of the parts that move upstream and downstream. Measuring this difference in time gives the speed of the passing flow.

The difference in transit time is usually on the order of nanoseconds. Hence, accurate electronics are required to perform this measurement, whether the time is measured directly or the frequency difference conversion is performed. The second one is more popular and involves receiving an upstream and downstream signal and involves anFFT analysis of the frequency difference between the waves.

Different Types of Industrial Sensors

System Considerations for Ultrasonic Flowmeters:

- Doppler shift flow meter is relatively cheap.

- The transit time flowmeter provides one of the few techniques for measuring non-conductive slurries and corrosive fluids.

- The most important weakness of the ultrasonic flow meter is its dependence on the characteristics of the fluid flow. For the same average flow rate, the meter can give different output readings for flow with different specifications.

Sepyani Industrial Group is ready to provide installation and sales services of all types of flowmeters and their use in industrial automation systems for flow control. You can visit our store called Dr. PLC to get more information about purchasing industrial parts and get in touch with our consultants by completing the consultation request form and WhatsApp.