Hydraulic Actuator

In this article, we intend to examine the hydraulic drive and its types. Stay with us.

Table of Contents:

- What is a stimulus?

- Application of stimuli or operators

- Types of stimuli

- Hydraulic actuators

- Hydraulic system components

- Types of hydraulic actuators

- Types of linear hydraulic actuators

- Advantages and disadvantages of hydraulic actuators

What is a stimulus?

Actuators are mechanical devices that convert various types of energy into motion. This action usually includes a control command. With each command, a change in the signal of the physical system occurs and then the desired force is created to carry out the given command. The command signal can be controlled automatically or by humans, which of course has a different energy source.

In fact, industrial actuators control industrial machines and allow parts to move linearly or non-linearly. This movement can include all types of operations such as closing, lifting, blocking and pushing out, etc. Typically, actuators are key members of industrial operations and production lines where they activate or deactivate pumps, valves, switches, and motors.

Usually, actuators direct and control mechanized movement. Types of movements include linear, rotational or oscillating movements. In other words, this movement can happen in one direction, in a circle or back and forth at regular intervals. Whenever a mechanized system commands any final movement, the presence of actuators is mandatory and without them the movement will be impossible.

Where are actuators or operators used?

It can be safely said that every industry uses different types of stimuli in a different way. Actuators are used and required in oil and gas processing, aviation and aerospace industry, military and defense industry, marine industry, mining, forestry, road construction, urban construction, electronic industry, automobile manufacturing, etc.

Operators are also used in the construction of equipment such as cranes, presses, drilling rigs, human lifters, coal crushers, rocket launchers, and other material handling equipment and automatic devices. If you choose an industry or field and check its details. You can see that the triggers are definitely used somewhere higher or lower.

What are the types of stimuli?

Actuators are divided into three main categories: pneumatic, hydraulic and electric.

There is another type of division based on the movement they perform. In terms of classification, it can be said that there are two categories:

- Linear motion operators

- Rotational motion operators

Linear operators themselves are divided into the following types:

- Pneumatic jacks

- Hydraulic jacks

- Linear servo motors

- Solenoid jacks

Rotary operators and actuators also include the following types:

- Types of rotary operators

- Electric motors

- Pneumatic motors

- Hydraulic motors

To choose the type of operator, it should be kept in mind that it must be selected. Then choose the appropriate operator according to whether the movement of the valve shaft is linear or rotary and what the amount of torque will be. In this article, hydraulic actuators are discussed.

Hydroc science and hydraulic actuators:

Hydraulics is the science of studying fluids under pressure. In fact, it can be said more simply that hydraulics is “doing work or producing power or movement by liquid under pressure”. It is interesting to know that hydraulic science has been used since ancient times and people used it to do their work. But this science was not known by this name, for example, they used water to move tree trunks and timber. Another example is the mill system and the use of water power to turn water turbines.

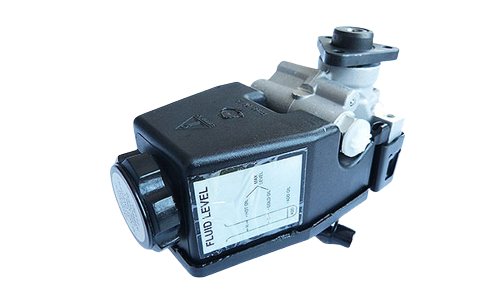

Today, hydraulics are used in the industry for material and waste presses, textile and paper related machines, casting machines, as well as door opener machines and plastic pressing machines, etc. Hydraulic actuators are very similar to pneumatic actuators and the only difference between them is the used fluid that is placed in them. Usually, in hydraulic actuators, oil is used to transmit power, but air or water, or even another fluid, may be used in the pneumatic type. In other words, hydraulic actuators, like pneumatic ones, are designed and produced with two modes: Normally Close and Normally Open.

The working principle of the hydraulic actuator is that it uses liquid pressure instead of air pressure of the tool to provide power and perform work on the diaphragm to move the valve. Almost all types of hydraulic actuators use a piston instead of a diaphragm to convert fluid pressure into mechanical power.

Hydraulic system components:

The most important components of hydraulic systems are:

Hydraulic tank:

Its function is to hold the required volume of fluid, take the heat of the system, deposit and settle solid pollutants in itself, and facilitate the exit of air and moisture from the hydraulic fluid.

Hydraulic pump:

It is responsible for converting mechanical energy into hydraulic energy. This work is done by transferring the fluid along the pipes and other connections of the hydraulic system. There are different types of hydraulic pumps, including gear, vane and piston. All these named types have different subgroups that are used for specific applications. Such as vane hydraulic pump with variable displacement or bent axis piston pump.

Hydraulic valves:

Valves are used in hydraulic systems to start, stop and direct the fluid flow. Valves can be activated and guided by means of hydraulic, pneumatic, electrical, manual or mechanical means.

Hydraulic actuators:

Hydraulic actuators convert hydraulic energy into mechanical energy. This can be done with the help of a hydraulic cylinder and piston that converts hydraulic energy into linear motion, or with the help of a hydraulic motor that converts hydraulic energy into rotational movement and work.

Types of hydraulic actuators:

Hydraulic actuators are classified into three types based on the action they perform:

- Linear operator

- Rotary operator

- Semi-rotary operator

1. Linear hydraulic actuators: A linear actuator is used for linear movement. They provide force or motion in a straight line, such hydraulic actuators are also called hydraulic cylinders.

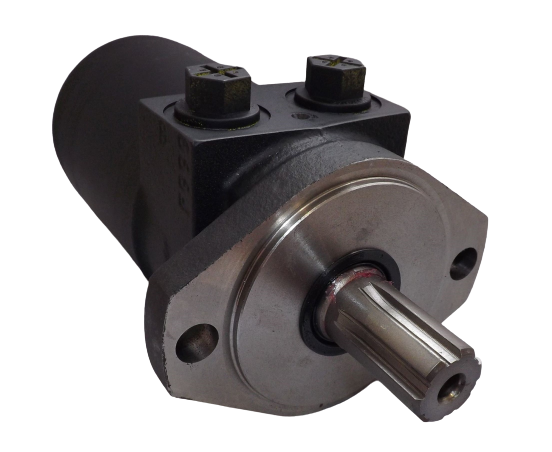

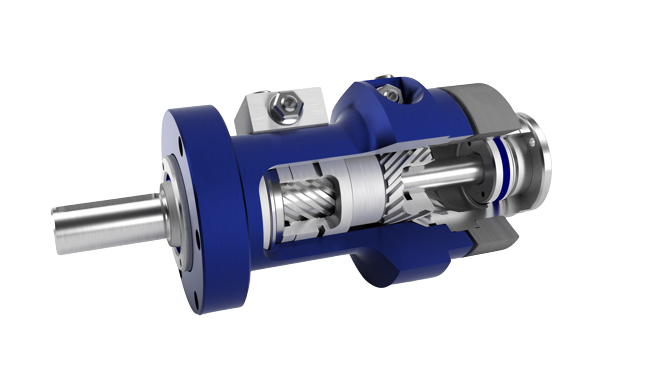

2. Rotary hydraulic actuators: A rotary actuator is used for rotary movements. They provide torque or rotational motion to the machine. Such hydraulic actuators are also called hydraulic motors. By using these operators, it is possible to obtain constant angular motion.

3. Semi-rotary hydraulic actuators: Semi-rotary actuators are used for turning with a slight angle. These actuators are capable of small angular movements that can create huge revolutions in movements below 360 degrees.

These named operators have their own types that we will discuss.

Types of linear hydraulic actuators:

Hydraulic cylinders can be of the following types:

Single-acting cylinders:

It consists of a piston inside a cylindrical housing. A rod is attached at one end. which can be connected on either side. On one side there is a valve for fluid entry and exit. They produce power in only one direction with the hydraulic pressure applied to the piston. After the piston is compressed, it is not returned to the first state by hydraulic force, but by a spring or gravity force.

Double-acting cylinders:

It consists of two pistons on both sides of the cylinder. There are two rods on both ends of the cylinder. Power transmission is done by both sides of the cylinder, so it has a more productive design. Two cylinder rods can withstand higher lateral loads and are resistant due to the additional bearing on each rod to withstand the load.

Telescopic cylinders:

They are generally formed by placing pipes together and operate on the principle of displacement. The tubes are supported by bearing rings, the innermost set of which have grooves or channels to allow fluid flow. The stop rings limit the movement of each section and thus prevent the pipes from separating.

Tandem cylinders:

A tandem cylinder is used when steering requires a large amount of force to be applied from a small diameter cylinder. Pressure is applied to both pistons, resulting in increased power output due to the large area of the piston and the small cylinder. The only drawback is that these cylinders must be longer than a standard cylinder in order to achieve power at the same rate because flow must be applied to both pistons simultaneously.

Rotary hydraulic actuators (hydraulic motors):

Hydraulic motors can perform the same function as an electric motor, but depending on the characteristics of the desired process, they have some advantages over electric motors. The size of hydraulic motors is much smaller. Because usually the hydraulic unit is located in an independent area from where it needs to move.

Advantages and disadvantages

Advantages:

- Hydraulic actuators can be away from the power station and the circuit, and without the stress of losing the source, and works only with hydraulic power and fluid.

- These types of operators can provide more power to do work than pneumatic or electric operators despite the fact that they are not very heavy equipment.

- They can produce 20 times more power than pneumatic actuators.

- Hydraulic actuators can withstand pressures up to 40 psi.

Disadvantages:

- Hydraulic actuators and hydraulic circuits, in general, tend to have some small leaks of hydraulic fluid in certain parts of the circuit such as joints, elbows, valves. Of course, these small productivity losses are usually negligible.

- To perform a linear or rotary movement, although in a short and small distance, to a large number of parts that are parts of the hydraulic circuit. Like a hydraulic power station, with pumps, tanks, valves, etc. required.

- Noise in power generation is another weakness because hydraulic circuits are generally longer than electric and pneumatic actuators and may not generate power continuously and smoothly.

Conclusion:

Sepyani Industrial Group is at your service with more than two decades of experience in the field of industrial automation, designing and setting up production lines, maintenance and… Also, you can visit our store site to get all kinds of pneumatic equipment, precision tools, industrial electricity, etc., and our technicians will guide you by providing free advice. Contact us by What’sApp.