What is SCADA?

SCADA stands for Supervisory Control and Data Acquisition. This system refers to a system consisting of a number of RTU remote terminal units that collect field data connected to a master unit through a communication system and display the obtained data to the master unit. It also allows the operator to perform remote control tasks.

Its other advantages include high efficiency, high reliability and most importantly, safer use. All this leads to a lower cost of the process compared to previous non-automated systems. The performance of the SCADA system depends on the comprehensive training of all personnel on how to use it.

What is Industrial Automation?

Important objectives of SCADA:

- Monitoring: continuous monitoring of voltage, current and… .

- Measurement: Measurement of variables for processing

- Data Collection: Repeated data collection from RTUs and Phasor Data Logger concentrators (PDC)

- Data communication: transmitting and receiving large amounts of data from the field to the control center

- Control: online real time control for closed loop and open loop processes

- Automation: Automatic switching operation of CB transmission lines etc.

Advantages of SCADA:

- Continuous monitoring of the process

- Real time control

- Automation and protection

- Launch and remote control

Major applications of SCADA:

- Show information

- Monitoring control

- Analysis of warnings

- Storage of information and reports

- Collect events continuously

- RTU processing/control

Application of SCADA systems:

SCADA can be used to manage any type of equipment. In general, SCADA systems are used to automate complex industrial processes in which human control is difficult. For example, in systems where there are more control factors that cannot be managed by operators in a control center. SCADA systems are widely used for control in the following areas:

1. Production, transmission and distribution of electricity

Power companies use SCADA systems to detect line current and voltage, monitor the operation of circuit breakers and power grid sections online or offline.

2. Water and sewage

State and city water companies use SCADA to monitor and control water flow, tank level, pipe pressure, and other factors.

3. Buildings, facilities and environments

Facility managers use SCADA to control HVAC refrigeration units, lighting, and intake systems.

4. Mass transportation

Transportation officials use SCADA to control the electrification of subways, trams, and electric buses. to automate traffic signals for rail systems; To track and locate trains and buses and to control railway crossing gates.

5. SCADA Traffic Signs

It controls traffic lights and traffic flow and detects out of order signals.

What are CNC milling and turning?

Features of SCADA:

In the following, you can see the important features of SCADA. It is capable of:

- It obtains quantitative measurements immediately and over time.

- Identifying, diagnosing and correcting errors as soon as they occur

- It measures processes over time and prepares reports and charts.

- Identify and eliminate defects over time and improve efficiency

Accurate control of the operator’s empirical knowledge:

SCADA provides a facility to precisely control the experiential knowledge of operators in the system. Sensors can be placed at any critical point in the process to be managed and controlled. As this technology advances, more sensors can be connected to improve the efficiency of SCADA.

The ability to observe the performance of large power processes in real time through GIS software (Geographic Information System) is one of these softwares that is widely used in electrical applications. With such am=n capability, it is possible to correct errors and detect them.

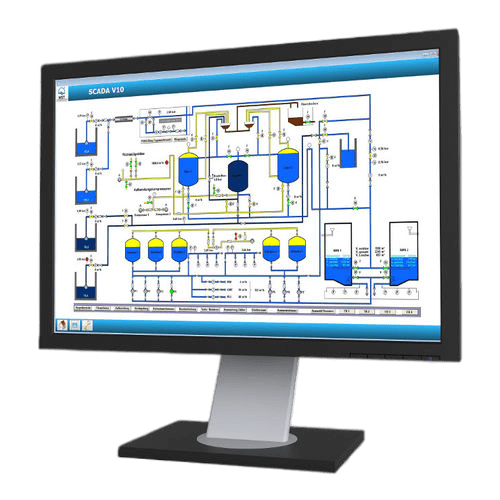

Concept of SCADA system:

SCADA refers to centralized systems that control and monitor entire sites or complex systems that are widely used in areas. Almost all control actions are performed automatically by RTUs or by programmable logic controllers (PLC).

The limitations of applying host control are basic monitoring-level intervention or override. For example, a PLC (in an industrial process) controls the flow of cooling water, the SCADA system allows to record any changes related to alarm conditions and set points for the flow (such as high temperature, reduced flow, etc.) and is displayed. In the following, we examine the types of SCADA architectures:

First generation: Integrated

In the first generation, mainframes were used for computing. At the time SCADA was developed, there was no network. Therefore, SCADA systems had no connection with other systems. That is, they were independent systems. Later RTU vendors designed wide area networks that help to communicate with RTUs. The use of communication protocols was proprietary at that time. There was a backup CPU connected to the bus in case the CPU failed.

Second generation: Distributed

In the second generation, information was shared between several stations in real time through LAN, and processing was distributed among several different stations. The cost and size of the stations have been reduced compared to the stations used in the first generation. The protocols used for networking were still proprietary, which caused many security problems for SCADA systems. Due to the proprietary nature of the protocols, very few people actually knew about the security of a SCADA installation.

Third generation: networked

The SCADA system used today belongs to this generation. Communication between the system and the main station is done through WAN protocols such as Internet Protocols (IP). Since the standard protocols used and networked SCADA systems are accessible via the Internet. The vulnerability of the system increases. However, the use of standard security techniques and protocols means that security improvements can be applied to SCADA systems.

security issues:

Since these systems are potential targets of terrorist cyber attacks and cyber war. Recently, the security of SCADA-based systems has been questioned. There is a misconception that SCADA networks are secure enough because they are physically secure. SCADA networks are also mistakenly thought to be secure enough because they are disconnected from the Internet. SCADA systems are also used to monitor and control physical processes such as water distribution, traffic lights, electricity transmission, gas transmission lines and oil pipelines and other systems used in modern society. Security is very important because compromising systems can have dire consequences.

Potential risks:

There are two major risks. The first is unauthorized access. Software, whether human access or resulting intentional modifications, virus penetration or other problems that could affect the control host device. The second threat is related to packet access depending on the network segments that host SCADA devices.

In many cases, there is less security in the actual packet control protocol. So anyone who sends packets to the SCADA device is in a position to control it. Often, SCADA users assume that VPN protection is sufficient and overlook the fact that physical access to SCADA-related network switches and jacks provides the capacity to bypass the security of SCADA control and software control networks.

SCADA vendors have solved this problem by developing specialized industrial VPN and firewall solutions for SCADA networks that are based on TCP/IP.

SCADA processes:

In the late 1990s, instead of using RS-485, manufacturers used open message structures such as Modbus ASCII and Modbus RTU. By 2000, almost all IO manufacturers introduced fully open interfaces such as Modbus TCP instead of IP and Ethernet.

SCADA systems are now compliant with standard network technologies. The old proprietary standards are being replaced by TCP/IP and Ethernet protocols. “Next generation” protocols support more IT using XML Web Services and other modern Web technologies. Some examples of these protocols include Wonderware’s Suite Link, GE Fanuc’s Proficy, I Gear’s Data Transport Utility, Rockwell Automation’s FactoryTalk, and OPC-UA.

Some vendors are beginning to offer application-specific SCADA systems that are hosted on remote platforms across the Internet. Hence, there is no need to install the systems at the end user’s facility. Major concerns are related to Internet connection reliability, security, and latency. The role of SCADA systems is becoming more colorful everywhere. However, there are still some security issues. To get more information, you can complete the free consultation request form so that our consultants will contact you as soon as possible.