Sanitary necessities and CIP device:

Before we go to the CIP device, let’s take a look at the definition of food hygiene based on the definition of the Codex Alimentarius Commission:

“All the criteria that must be followed in the production, processing, storage and presentation of food in order to have a healthy and high quality food product. health reaches the consumer”.

Food hygiene is very important, first of all, from the point of view of the healthiness of the food and then its high edible quality, and in order to achieve these goals, it is necessary to implement the following:

- Healthy raw materials, especially raw materials such as meat, milk, eggs, which are the basic ingredients of various foods, and if they are contaminated, they will cause the spread of dangerous diseases. As a result, food hygiene in the above products starts from live animals. Reviewing before and after slaughtering during meat production and examining dairy animals during milk production is the first effective step in the implementation of food hygiene of animal origin.

- Researches in the field of the situation that cause health and food quality risks and inventing methods such as CIP that are effective in solving the above situation.

- Carrying out strict health controls in the preparation, production, packaging, storage, transportation and distribution of food.

As a result, food hygiene becomes one of the applied sciences, which implies having sufficient assumptions in the field of natural sciences such as medicine, chemistry, parasitology, microbiology, toxicology, ecology, biology and epidemiology. In the rest of this article, we will get to know in detail one of the methods of maintaining the principles of hygiene in the food industry, that is, disinfection by the cip device.

What is a cip device?

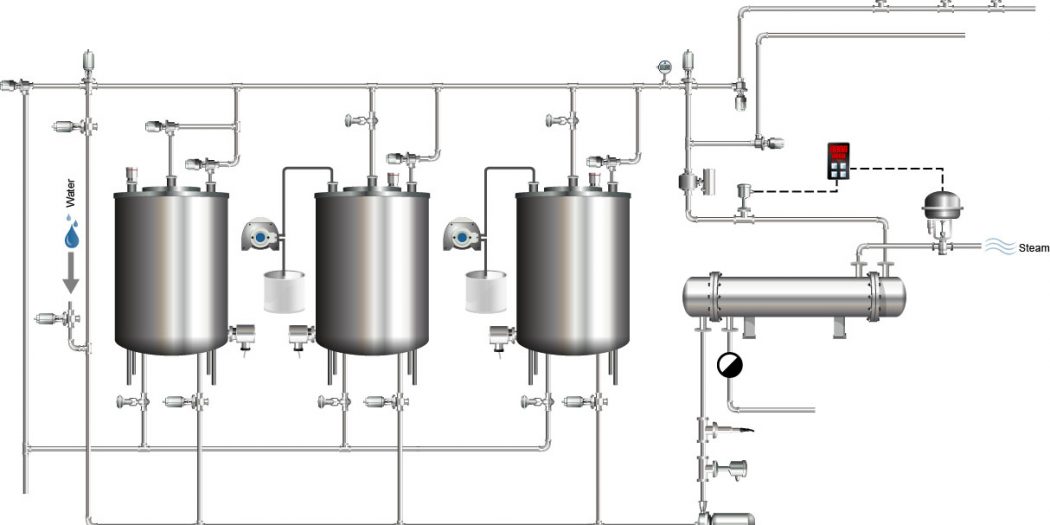

CIP is an abbreviation of three words Cleaning In Place, which means washing in place. The CIP system is a method of cleaning the internal surfaces of pipes, ducts, production equipment, filters and related connections in factories, without the need for human power, manual intervention, and the separation of parts or parts of the device.

Until 1950, the parts of the factory machines were first separated from each other and then cleaned and washed manually. Various industries such as dairy, beverage, processed food, pharmaceutical and cosmetic industries that require a high degree of hygiene, CIP system is considered an extremely important advantage in them. This method is fast and far more repeatable than other methods.

How the sanitary condition of food and beverage production is very important, as a result, factories should set a high standard for this condition in order to prevent contamination and breakdown of products, the CIP system will be able to clean quickly, efficiently and efficiently. Ensuring that all factory procedures are used.

Investigating how the cip device works:

This system will disinfect and wash the devices by circulating the cleaning solutions through the nozzles. Automatic CIP systems are different from each other in terms of mechanism, operation and level of automation. In fact, the phases of the washing system completely depend on the production and manufacturing lines of the desired food, but usually four models of liquid soda, acid, hot water and sterile water are used. They say that it can be designed in two models of round-trip lines.

A large number of companies and factories are trying to improve the operation of the CIP system by reducing the operation time as well as reducing the consumption of water and chemicals. One of the new methods in this field is the use of an oxidizing disinfectant instead of nitric acid. At the same time, this compound has a higher effect on contamination and microbial sediments at low temperature, and due to no need for final washing with hot water (due to the low residue of this compound), the use of fuel for heating water is reduced.

Types of cip system:

CIP systems have a lot of variety and each of these washing systems has its own special efficiency, and other cases are considered among the most important CIP systems with a lot of use in the industry, these include the following:

1. single pass system

The structure of this machine is such that a basic cleaning solution is used to clean the machinery. After the emptying operation is done, the rinsing phases are completed, and along with the injection of the disinfection solution, other contaminations and microbes will be destroyed, and finally the rinsing phases are realized.

2. Recirculation system

The structure of this device is also such that the disinfectant solution is produced in an additional tank and is used for disinfection and cleaning. On the other hand, the rotation of this solution in the machine continues until the end of the disinfection operation, and after washing, the disinfectant disappears during the rinsing process. The cleaning and cleaning that this circulation device brings is definitely more than the cleaning of the cip device introduced in the previous case.

Review the steps of the cip system:

If you decide to buy the CIP system, it is necessary and necessary to have relative familiarity with the phases of CIP car washing. The following are among the most important steps of washing the CIP device:

- In the first step, all industrial equipment are washed by means of high pressure.

- In the next step, alkaline materials will be used to completely dissolve and wash away the fats and proteins.

- After that, washing with water is done in this step.

- In the fourth step, disinfection is done with acidic materials until the alkaline surface of the machinery is neutralized. In this step, all mineral deposits will also be destroyed and in fact the equipment will be disinfected.

- In the final step, rinsing is done with cold water.

What parts are cip systems made of?

Perhaps knowing that the cip washing system and machines of this kind consist of unique parts. If it is interesting for you, we will introduce these parts in the following:

- water resources

- Measuring tools

- Touch monitor

- Dosing system

- Process recorder chart

- Chemical pumps

- Automatic valves

- Duran valves with the ability to change speed and pressure

- Input and output tanks

- PLC controller

What is CIP?

In the food industry, washing and disinfecting tanks are extremely important. As a result, sources must always be clean and ensure the absence of any microbial contamination, for this purpose, CIP operation is performed. The process of spraying disinfectants inside and outside machines and sources for washing and disinfection is called CIP. This process is generally used for large machines that do not have the condition of floating in disinfectants. Milk storage sources should be washed every hour and disinfected before each new milk sample. Milk sources will be sampled every two hours for microbial tests.

CIP steps preferably:

In order to wash and disinfect milk sources, the following steps can be taken:

At the beginning, all the tank will be washed with water, after that hot water steam (temperature 85°C) or hot water will be used for 10 to 20 minutes in order to prevent the deposition of salts in the mixer and other parts. In the next step, it should be He used manual washing of tanks.

In this way, with the efficiency of cleaning and disinfecting materials, he completely washed the internal parts of tanks, milk transfer pipelines, transfer tankers, etc. Care should be taken and do not use metal cleaners that cause scratches and corrosion on the surfaces of parts and tanks. Disinfectant must have a pH lower than 10, or chlorine-alkaline detergent should be used. In the final step with water efficiency, disinfectants should be completely removed from the surfaces of the tanks. After thorough washing with normal water, the tanks will be exposed to the air to dry completely.

In order to wash tanks, CIP devices can be used. These machines are available in the market in semi-automatic and automatic form, and experts and consultants of Sepyani Industrial Group will be with you in purchasing, setting up and training the CIP specialist workforce.

Effective factors on the operation of the CIP system:

The temperature of the disinfectant solution – increasing the temperature increases the power. In fact, the molecules will destroy the pollution with a higher acceleration.

The density of the disinfectant substance – by increasing the density of the chemical substance. Basically the disinfection operation will be performed better because the ability of the substance to connect with the surface will increase.

The contact time of the disinfectant solution with the parts – increasing the contact time increases the efficiency of the disinfection process.

The mechanisms of the CIP device are different:

- Single tank mechanism – washing and rinsing is done by one tank.

- Two tank mechanism – one for washing with water and the other for rinsing.

- Three-tank mechanism – washing with water, rinsing and recycling is done by three different tanks.

- Four tank mechanism – washing with water, rinsing, washing with alkaline, acid, disinfectant and extracting each have separate tanks.

Advantages of CIP system:

- No need for manpower

- Short time of disinfection process

- Excellent health status (the automatic system works more efficiently than the manual system.)

- More security

CIP system frameworks:

- Its installation and commissioning should be done by experienced experts (the experts and experienced engineers of Sepyani Industrial Group are always by your side in doing this task.)

- The flow rate or pressure of the chemicals used must be constantly measured and checked.

Some of the functions of the CIP system:

- Liquid fillers, especially in the dairy industry

- Meat cooking systems

- Salad production systems

- Conveyors

- Meat slicers

Considering the increasing value of energy due to economic policies, the requirement to optimize production activities is felt more than before. In this article, the new method of CIP process and the use of peracetic acid (peroxidin) and its advantages are mentioned, and it is tried to make economic savings by making changes in the CIP process, focusing on the quality of the product.

New method of CIP:

In the new CIP method, which is used by food industry factories in advanced countries. A high-level oxidizing and disinfecting agent replaces nitric acid. Due to not using water (hot water) in the last step of CIP, fuel consumption for heating water will be reduced. Meanwhile, due to the lower efficiency of the pumps, the amount of electricity used will also decrease.

In food manufacturing factories, complete cleaning and disinfection of parts is one of the important and main steps in production operations. The main part in the design of the food production plant is the cleaning routine of the equipment in contact with the food products. In food production, maintaining the highest sanitary conditions is a requirement that should be considered one of the main pillars of production.

Final word:

CIP process is the abbreviation of three words Cleaning In Place. The cip device is widely used in most industries, especially food production and packaging industries (dairy, beverage, protein, etc). The presence of the cip device is considered one of the most important advantages of the production line. In this way, washing the machine is done easily without the need of manpower or a lot of equipment.

Sepyani Industrial Group, with the cooperation of experienced engineers and consultants, is able to design and build exclusive production lines considering the customer’s goals and needs. Construction of CIP lines is one of the services of Sepyani Industrial Group. To get more information, you can contact us by completing the consultation request form and WhatsApp.