What is a stepper motor?

A stepper motor is an electromechanical device that converts electrical power into mechanical power. Also, it is a brushless and synchronous electric motor that can divide a full revolution into many steps. The position of the motor can be accurately controlled without any feedback mechanism, as long as the accuracy of the stepper motor is suitable for the project. Stepper Motors are similar to switching reluctance motors. A stepper motor uses the theory of how magnets work to rotate the motor shaft by generating a pulse of electricity at a precise distance. The stator has eight poles and the rotor has six poles. This rotor needs 24 electrical pulses to travel 24 steps and complete one revolution. So the rotor moves exactly 15 degrees for every electrical pulse the motor receives.

How to build and work with a Stepper Motor?

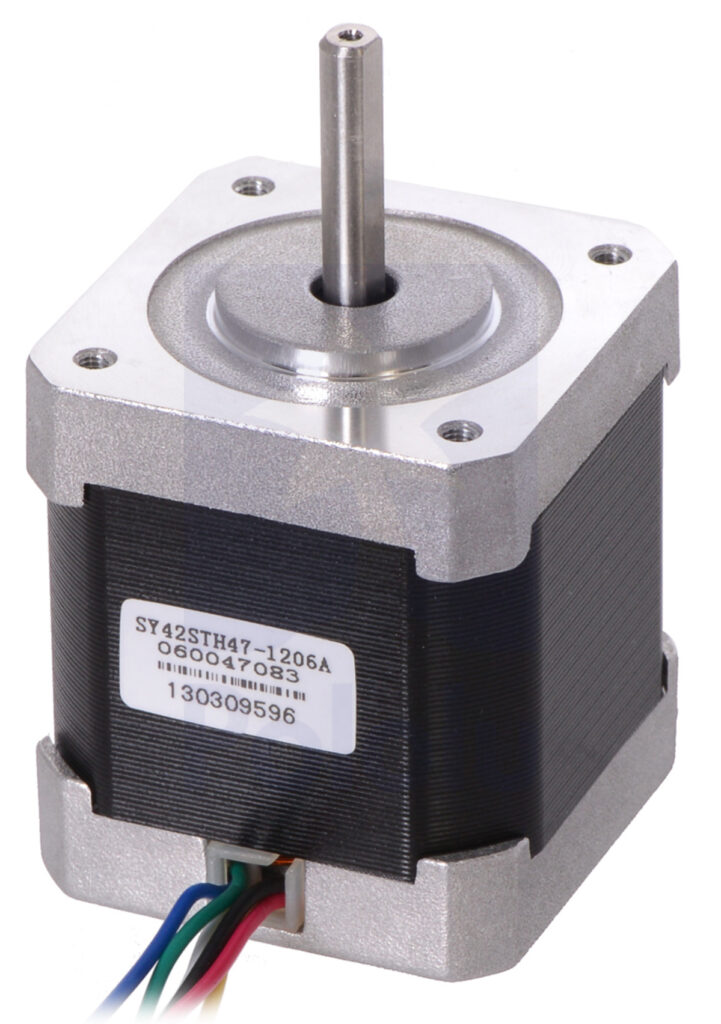

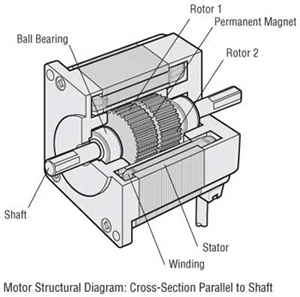

How to build a stepper motor is quite similar to a DC motor. It consists of a permanent magnet like rotor which is located in the middle and rotates when power is applied to it. The stator is a magnetic coil wound around the stationary part of the motor. The stator is placed close to the rotor so that the magnetic fields inside the stators can control the movement of the rotor.

Stepper Motor can be controlled by electric pulse to each stator one by one. So the stator becomes magnetized and acts like an electromagnetic pole that uses the repulsive energy on the rotor to move forward.

The working principle of the stepper motor is electromagnetism. It consists of a rotor made with permanent magnets while a stator is made with electromagnets. When the power supply is connected to the stator winding, a magnetic field is created inside the stator. Now the rotor in the motor starts moving with the rotating magnetic field of the stator. So this is the basic working principle of this engine.

In this motor, there is a soft iron enclosed through the electromagnetic stators. The poles of the stator as well as the rotor do not depend on the type of stepper. When the stators of this motor are connected to the source, the rotor rotates to align itself with the stator, otherwise it will have the minimum distance through the stator. In this way, the stators are activated in series to rotate the stepper motor.

Stepper motor startup methods

Stepper motor starting methods can be possible with some special circuits due to their complex design. There are various techniques for starting this engine, some of which are discussed below.

A state of stimulation:

The main method of starting a stepper motor is an excitation mode. This is an old method and not used much now, but you should know about this technique. In this technique, each phase in the stator is started alternately with a special circuit. This magnetizes and demagnetizes the stator to move the rotor forward.

All step setup:

In this method, two stators are connected to the source at the same time in a very short period of time. This method results in high torque and allows the motor to start a large load.

Half-step setup:

This method is related to the full step starting method .because two stators are placed next to each other . And so that the first one is connected to the source while the third stator is connected to the source after that. This type of cycle starts the motor to switch two stators first. and then the third stator. This technique leads to improving the working resolution of the stepper motor. and reducing the torque.

Setting up in micro steps:

This method is used more because of its accuracy. The variable step current is supplied by the stepper motor starter circuit to the stator windings in the form of a sinusoidal waveform. The accuracy of each step can be increased with this small step flow. This technique is widely used because it provides high accuracy and also greatly reduces noise during operation.

Stepper Motor & the way it works

The difference between a stepper motor and a DC motor:

Stepper motors work differently from brushed DC motors in that they operate by applying a voltage to them. Stepper motors, on the other hand, effectively have multiple toothed electromagnets arranged around a central gear-shaped piece of iron. In addition, the electromagnet is fed by an external control circuit, for example, a microcontroller.

Stepper motor rotor rotation factors:

It is powered by electromagnets to rotate the motor shaft. This causes the teeth of the gear to be magnetically attracted to the teeth of the electromagnet. At the point where the teeth of the gear are aligned with the first electromagnet, they are slightly apart from the next electromagnet. So when the next electromagnet is energized and the first is disconnected the gear rotates slightly to align with the next magnet and the process repeats from there. Each of those partial turns is called a step, which makes up the correct number of steps for a complete turn.

Why does the stepper motor not work continuously?

According to what was mentioned, the motor can be started with a high precision controller. The stepper motor does not rotate continuously, but in steps. 4 coils are placed on the stator at an angle of 90 degrees. Stepper motor connections are determined by how the windings are connected to each other. In a stepper motor, the windings are not connected. It has a 90-degree rotation stage, where the coils are connected to the source in cycle order. and determine the direction of shaft rotation.

The operation of this motor is shown using a switch. So the coils are activated in series at 1 second intervals. The shaft rotates 90 degrees each time the next coil is activated. Its low speed torque varies directly with current.

Types of stepper motor

There are three main types of stepper motors, which are:

- Permanent magnet

- Synchronous hybrid

- variable reluctance

Permanent magnet stepper motor

Permanent magnet motors use a permanent magnet (PM) in the rotor and operate on the attraction or repulsion between the rotor PM and the stator electromagnets.

This is the most common type of stepper motor. compared to the different types of stepper motor available in the market. The motor includes permanent magnets in the motor construction. This type of engine is also known as can-stack engine. The main advantage of this stepper motor is lower manufacturing cost. It has 24-48 steps for each rotation.

Variable reluctance stepper motor

Variable reluctance (VR) motors have a simple iron rotor and work on the principle that minimum reluctance occurs with minimum gap. Hence, the points of the rotor are attracted to the poles of the stator magnet. As the name suggests, the angular position of the rotor mainly depends on the reluctance of the magnetic circuit that can be created between the teeth of the stator as well as the rotor.

Hybrid synchronous stepper motor

Hybrid stepper motors are so named because they use a combination of permanent magnet (PM) and variable reluctance (VR) to achieve maximum power in a small size.

The most popular type of motor is the hybrid stepper motor because it performs well in terms of speed, step resolution, and holding torque compared to a permanent magnet rotor. But this type of stepper motor is expensive compared to permanent magnet stepper motors. This motor has the characteristics of both permanent magnet and variable reluctance stepper motors. These motors are used in cases where a smaller step angle is needed such as 1.5, 1.8 and 2.5 degrees.

How to choose a stepper motor?

Before choosing a stepper motor for your needs, it is important to check the torque-speed curve of the motor. Therefore, this information is provided by the engine designer and is a graphical representation of the engine torque at a certain speed. The torque-speed curve of the motor must be perfectly matched to the required application. Otherwise, the expected performance of the system cannot be achieved.

Stepper Motor vs. Servo Motor

Servo motors are suitable for high torque and high speed applications while stepper motors are cheaper. Therefore, they are used in cases where high holding torque, with low to medium acceleration, flexibility in open loop or closed loop operation is required.

Stepper and DC motor

Both stepper and dc motors are used in various industrial applications but there are major differences between them.

Advantages:

The advantages of the stepper motor include the following:

- Simple structure

- It can work in an open-loop control system

- Low maintenance cost

- It works in any situation.

- High reliability

- The rotation angle of the motor is proportional to the input pulse.

- The engine has full torque at rest.

- Accurate positioning and repeatability of movement because good stepper motors have an accuracy of 3-5% of a step.

- Excellent response to start, stop and reverse.

- Very reliable because there are no brushes in the motor. Therefore, the life of the engine depends solely on the life of the bearing.

- Motor response to digital input pulses allows open-loop control and makes motor control simpler and less expensive.

- Very low synchronous speed can be achieved with the load directly coupled to the shaft.

- It has a wide range of speeds because the speed is proportional to the frequency of the input pulses.

Disadvantages:

The disadvantages of the stepper motor include the following:

- Low efficiency

- Engine torque depends on speed and decreases with high speed.

- Low accuracy

- It has no feedback to identify possible missing steps.

- Low torque relative to inertia

- Extremely noisy

- If the engine is not properly controlled, resonance may occur.

- This engine is not suitable for working at very high speeds.

- Requires a control circuit

- Compared to DC motors, it consumes more current.

Application of stepper motor

Among the applications, the following can be mentioned:

Industrial machines: They are used in automatic machine tool production equipment.

Security: New monitoring products for the security industry.

Medical: They are used inside medical scanners, samplers, as well as inside digital dental photography, fluid pumps, masks, and blood analysis machines.

Electronics: In cameras for automatic digital camera focus and zoom.

What are CNC Milling and Turning?

Sepyani Industrial Group is ready to provide advice in the fields of precision instruments, equipment and industrial tools, including stepper motors, by using the business and skills of experienced engineers in the field of industrial automation. You can contact us by What’sApp for more information.