Types of Pasteurizers

Before going to the types of pasteurizers, it is good to know what pasteurization is and how pasteurizers are used.

What is pasteurization?

Pasteurization is a process in which all disease-causing bacteria are removed from a food or liquid, as well as 90 to 99 percent of other bacteria that may affect product quality. Basically, pasteurization kills bacteria with high heat and helps reduce the transmission of diseases such as typhoid, tuberculosis, scarlet fever, polio and dysentery. For this reason, pasteurization is the most important function of a milk. Follow this article to get to know the types of pasteurizers.

Pasteurization Methods:

There are different levels and methods of pasteurization based on the temperature used to heat a product and the amount of time spent doing so. Deciding which pasteurization method to use depends largely on the type of product you are working with. When it comes to the pasteurization of dairy products such as milk and cream, the two most common types are vat pasteurization and HTST pasteurization.

Maintenance of Dairy Production Lines

VAT pasteurization:

VAT pasteurization, which is also called batch pasteurization or storage method, is one of the original pasteurization methods. In addition to processing milk, this method is usually used in dairy industries when processing yogurt, cheese, ice cream mix, etc. VAT pasteurization kills bacteria by heating each drop of milk or cream in properly designed and operated equipment for half an hour (much longer than most forms of pasteurization).

Recommended temperature for VAT pasteurization:

To pasteurize milk, it is necessary to heat the milk at 145°F (63°C) for 30 minutes. If the milk product has a fat content of 10 percent or more, or total solids of 18 percent or more, or if it contains added sweeteners, the specified temperature must be increased by 5 degrees Fahrenheit (3 degrees Celsius). It is possible to have both butter grains and cream plugs in milk and cream. Stirring is essential to achieve the right consistency and texture, as well as quick and even heating. Improper stirring will cause scabbing.

Heating and Stirring method for pasteurization in VAT:

Finding the right balance between heating and stirring is important for the VAT pasteurizer to work effectively. If the heating temperature is too low, the temperature of the milk product will not rise quickly.

If the heating temperature is too high, the milk product may cook on the heating surface. The speed of heating is affected by the ability of your stirrer to move and keep the product away from the heating surface. However, speeding up your mixer won’t necessarily give you the desired results. Agitators are designed for specific speeds and highly efficient agitators may require high heating water temperatures. An imbalance between the heating level and the type and speed of your stirring can lead to improper pasteurization.

Storage period for VAT pasteurization:

VAT pasteurization must be done at high temperature for a long time. During the storage period, the tank should remain closed to prevent cooling during pasteurization.

This method must have an air space heater to maintain the air above the product at 145°F or higher. Outdoor heaters also ensure the pasteurization of milk droplets that splash over the sides of the tank and condense inside the condensate cap. The bottom and sides of the bowl should be insulated or jacketed to maintain the proper temperature during the storage period.

HTST pasteurization:

HTST pasteurization stands for High Temperature Short Time Pasteurization and is also known as flash pasteurization or continuous method. This method has become one of the most common pasteurization methods today. HTST pasteurization is a continuous process that efficiently and effectively destroys microorganisms in milk products.

Recommended temperature for HTST pasteurization:

For HTST pasteurization, the milk product must be rapidly heated to a temperature of at least 161°F (72°C) for at least 15 seconds, followed by rapid cooling. If the milk product has a fat content of 10 percent or more, or total solids of 18 percent or more, or if it contains added sweeteners, the specified temperature must be increased by 5 degrees Fahrenheit (3 degrees Celsius).

Components of an HTST pasteurization system:

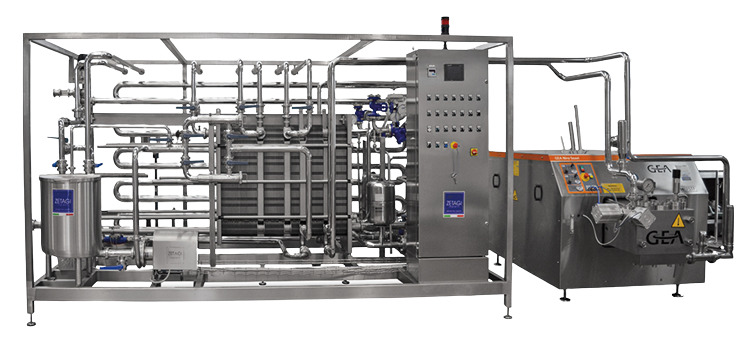

The HTST pasteurization system is a modular unit that includes a plate and frame heat exchanger, stainless steel balance tank, pumps, holding pipe, valves and controls. In fact the heat exchanger sends the product through a series of stainless steel plates. The product flows on one side while the heating medium flows on the opposite side to increase the temperature of the tap.

Advantages of HTST pasteurization:

VAT pasteurization is the oldest method for pasteurization of food products, but short time with high temperature has been the focus of many food industries over the years. Some of the benefits of HTST include:

- Large equipment capacity that allows more volume at a time

- The continuous process allows the process to begin with pasteurization

- High energy consumption

- Minimal possibility of damage to the milk product

- Full restoration has been used

- The equipment is easy to clean and sterilize

- Thermophiles are less troublesome

The only problem with that?

Exposure to extreme temperatures often changes the taste of food as well as its nutritional value. Believing that none should be sacrificed for safety and preservation concerns, and with more scientific advances as well as increased public interest in clean food, more and more manufacturers are beginning to use the High Pressure Processing (HPP or Pascalization) system.

HPP effectively removes most pathogens and other harmful microorganisms and extends shelf life, but does not alter its nutritional content, color, or flavor.

What is Industrial Automation?

2 common types of pasteurization equipment:

Take a look at two common types of high pressure pasteurization equipment:

1. Water tanks for pasteurization of prepackaged foods:

Some prepackaged liquid and solid foods can be pasteurized using a large steel tank filled with a liquid (usually water). After loading the packaged food into the tank, the pumps apply pressure that changes the cellular structure of the food, effectively preventing cell division and killing most microorganisms.

According to food science research at Rutgers University, “fruit and vegetable products such as juices, salsas, sauces and meat products such as deli meat and poultry and seafood such as shellfish and fish products” can be processed using the high-pressure pasteurization technique. The tank method is able to process many food items at once and is a good choice for high volume producers.

2. Homogenizer for liquid and semi-solid pasteurization:

Liquids and some semi-solid products can also be pasteurized with high-pressure homogenizers, which use a hydraulic pumping system to pressurize and sterilize them.

It passes them through a series of tubes. The homogenizer then ejects the product through a small orifice with a pressure drop that ruptures the cell and divides the product into equal-sized pieces that are easily and evenly mixed.

Combining the process of pasteurization and homogenization allows producers to manage their time more effectively, reduce energy consumption and waste, and acts as a suitable alternative to thermal pasteurization in the milk and juice industries in particular.

Pasteurization vs. Homogenization

Types of dairy pasteurization:

There are three types of dairy pasteurization:

- pasteurized milk

- Pasteurized cheese

- Pasteurized ice cream

Milk pasteurizer machine:

- MIP milk pasteurization equipment is designed specifically for thermal processing of milk and is the most economical model.

- Functional characteristics of pasteurized milk

- It can be combined with a processing line to produce cheese.

- The stirring motor with low speed (30 rpm), for easy cleaning and service, is installed on a special lifting base on the door.

- Fully opening stainless steel door

Cheese pasteurizer machine:

Basically, MIP cheese pasteurizer is a reliable and highly practical solution for pasteurization and coagulation of milk in one tank, which saves equipment cost, space and user time. Functional characteristics of pasteurized cheese:

- Powerful agitator motor, protected by stainless steel cover, controlled by inverter for fine adjustment of agitator speed.

- Pasteurized stainless steel controller with stir switch (clockwise or counterclockwise), LED indicators and emergency switch to stop stirring immediately.

- DN80 outlet valve for quick draining of liquids

- Installing the stirring motor on the movable and rotating stainless steel arm

- Removable stainless steel legs for faucet

- Durable and high tensile movable stainless steel blades for cutting coagulated mixture

- Fully detachable stainless steel door of separator type

- Detachable special stainless steel filter to keep cheese curds while emptying the container

Ice cream pasteurizer machine:

- MIP ice cream pasteurizer is a very practical solution for pasteurizing and mixing ice cream mix.

- Technical specifications of the ice cream pasteurizer

- Powerful stirring motor with rotation of 3000 rpm

- Stainless steel mixer with special blades

- Stainless steel blade guard

Functional features:

- The stirring motor is installed on the fixed part of the door for absolute stability.

- Openable and removable covers for easy filling of raw materials in the container

- Valve inlet with low floor system

Choosing the pasteurization method:

There are many things to consider when trying to decide which pasteurization method is best for your application. The most important factors to consider are your budget, the volume of product you are pasteurizing, and the heating rate you want. Small-scale dairy operations are usually done with vat pasteurization.

When it comes to finances, the maintenance method is the low-cost option. If you are working with smaller batches, lower temperatures and longer times may be more ideal. Processing plants using less than 1,000 gallons per day may also use a pasteurized tank as a storage tank. Standardization and addition of vitamin concentrate can be done before heating in VAT pasteurizer.

If a processing plant is handling excessive volumes, HTST will be the most economical and successful option. HTST systems are designed to work with increased quantities and higher efficiency. But since the continuous method requires more components, it can be more expensive than the maintenance method.

Other types of pasteurization:

There are several other pasteurization methods to learn, each with their own advantages and disadvantages that can affect your performance in different ways. One common method is the shorter higher heat time (HHST), which is a similar process to HTST, but uses higher temperatures for a shorter time and requires slightly different equipment.

Another type is ultra-high temperature (UHT), also called aseptic processing. With UHT pasteurization, dairy products are heated for only a few seconds at temperatures higher than those used for HHST pasteurization before being rapidly cooled. There are also a variety of non-thermal pasteurization methods that can increase stability and efficiency when converting raw food into final products. These include high pressure processing (HPP), pulsed electric field (PEF) and microwave volumetric heating (MVH).

Conclusion:

In today’s Sepyani article, we discussed pasteurizer devices. First, we examined the concept of pasteurization and then reviewed the types of pasteurization processes and finished the article with the types of pasteurizer devices. After reading this article, if you have questions or doubts about pasteurizers, you can get help from Sepyani experts free of charge.

Also, to buy the mentioned devices and other necessary equipment and know their price and technical specifications, you can visit our store section. For more information, contact us now through the consultation request form and WhatsApp.