Electric Motor

In recent years, scientific advancements have greatly contributed to the improvement and development of various aspects of life. Due to One of these areas is the construction of electric motors in the industrial sector. Because Tesla built a rotating magnetic field in 1882 and used it as a mechanical force. Today, Tesla’s invention is called the second industrial revolution. In fact, Tesla provided a way to produce electricity more easily and transport it over long distances. A few years later, Mikhail Asibovich invented the cage rotor three-phase motor, which is widely used today. As a result To learn about the operation and applications of electric motors, you can read this article.

What is an electric motor (electromotor)?

An electric motor, also known as an electromotor, is a machine that converts electrical energy into mechanical energy. Therefore It is the basis for any mechanical movement. The general structure of these motors is based on a conductor that carries an electric current, which is placed under the influence of a magnetic field. Thus This process results in a force being applied to the conductor carrying the electric current, which converts electrical energy into mechanical energy. Electric motors are divided into two groups: rotary and linear.

However, most electric motors are of the rotary type. Consequently A rotary electric motor consists of two parts: a stationary part called the stator, which is usually embedded inside the motor, and a moving part called the rotor. The force produced by the magnetic field in the stator causes the rotor to rotate around its axis. Electric motors can operate with both AC and DC currents, depending on their internal structure.

Electric motors are widely used in industrial automation and production lines. For consultation and installation of production lines, as well as purchasing industrial automation PLC equipment and electrical equipment, you can contact the Sepyani Industrial Group.

Getting to know the definitions and corrections about the electric motor:

To better understand the operation and structure of an electric motor, we must first become familiar with basic electrical concepts and terminology.

- Electric Current: The rate of change of electric charge over time, measured in amperes with an ammeter.

- Electric Work: The changes in voltage over time, measured in watts per second.

- Volt: The potential difference between two points, which generates a force that moves free electrons.

- Potential Difference: This quantity causes the flow of current in an electric circuit. Its unit is volts and can be measured using a voltmeter placed in parallel with the circuit.

- Rated Current: The amount of current that a device can handle without overheating or exceeding its mechanical capacity is called rated current.

- Ohm: The unit of electrical resistance, meaning that if a voltage of one volt and a current of one ampere pass through a circuit, the resistance will be one ohm.

- Watt: Indicates the amount of energy produced in a device.

- Magnetic Field: A field created by a magnet that is used to move electrons within conducting wires.

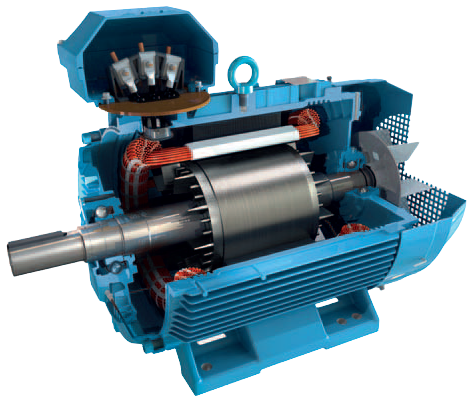

What parts do electric motors consist of?

Electric motors consist of 9 separate parts. These sections include the following:

1- Rotor:

The mobile part of an electric motor is called the rotor. In fact, the electrical energy that is converted into mechanical energy is provided in the rotor. Conductive blades are embedded inside the rotor, which cause the current to move and are in contact with the magnetic field formed with the help of the stator. As a result, forces are generated to start and rotate the shaft. Of course, in some types of electric motors, the rotor has an iron core structure and the conductive blades are embedded in the stator. But in any case, the general structure of the rotor is in this way.

2- Stator:

The stationary part of an electric motor, which has wire coils or conductive blades and creates a magnetic field, is called the stator. Interaction between the field created by the stator and the rotor causes rotation and movement of the rotor. The shaft is located at the center of it.

3- Bearing:

Bearings are installed at the beginning and end of the shaft in an electric motor to make it easier for the rotor to rotate around its axis. The shaft can transfer its mechanical force through the bearings.

4- Coil:

Coiled wires placed in a box called a coil are called winding or poles. The winding is often made of copper. The stator can control the rotation through the magnetic field difference between the winding and the rotor, which is capable of controlling the rotation by passing an electric current. In fact, these windings are what control the rotational speed of the electric motor. The more poles there are, the slower the motor will rotate. Bearings are installed at the beginning and end of the shaft in an electric motor to make it easier for the rotor to rotate around its axis. The shaft can transfer its mechanical force through the bearings.

5- Air gap:

The gap between the rotor (moving part) and stator (fixed part) in an electric motor is called an air gap. The air gap increases the magnetic flux, and if it is slightly larger than the standard value, it will cause a significant increase in current and generate a lot of noise. Therefore, it is better to keep this gap as small as possible.

6- Bowl:

This part of the electric motor, which is located in the middle of the pages and contains bearings, is responsible for fully and controlled by guiding the rotational mechanical current.

7- Shell:

The housing, which is made of cast iron or aluminum and houses all parts of the electric motor, is called the casing.

8- Fan:

A fan is installed at the end of the electric motor, in the end of the shaft, to cool the electric motor by directing airflow from outside into the shaft.

9- Power supply:

As the name suggests, electric motors operate with electrical current. The power source for an electric motor can be either alternating current (AC) or direct current (DC). However, DC current can be converted to AC current through the use of inverters. A fan is installed at the end of the electric motor, on the shaft, to cool the motor by directing outside airflow into the shaft.

What is CIP? Everything about it

How does the electric motor work?

If you are not familiar with electrical engineering concepts, the operation of an electric motor may seem complicated. However, we have tried to explain it in the simplest way possible. After electrical energy enters from the power source to the stator, the wire coils located on both sides of the stator core become magnetic. At this stage, a rotating magnetic field is created by the wire coils, which pulls the conductive bars out of the rotor and behind it. The rotor’s rotation provides the mechanical force needed for use in machinery.

Classification of electric motors based on input current:

As previously mentioned, some electric motors operate with direct current (DC) and others with alternating current (AC). With this characteristic, electric motors are divided into two groups.

- DC or Direct Current Electric Motor

- AC or Alternating Current Electric Motor

In the following, we will explain and introduce both. Additionally, Siemens industrial automation is one of the best brands available in providing electric motors and industrial automation equipment, which can meet users’ needs for electric motors and automation equipment with the best products and superior quality.

DC electric motors:

This type of electric motor has an armature made of electrically conductive iron. The commutator is a rotary switch. DC motors have different types, including:

- Series DC motor: They have high starting torque and are used in industries such as impact presses, hydraulic lifts, and cranes.

- Shunt DC motor: This type has maximum torque at nominal speed. Therefore, it is suitable for industrial fans and blowers. It is important to note that these types of electric motors should not be operated under heavy loads, as the high pressure on the armatures will damage the motor.

- Compound DC motor: This type of electric motor combines the characteristics of both series and shunt groups and is divided into two categories: additional compound and subtractive compound.

AC electric motors:

This type of electric motor is widely used in both household and industrial sectors. Some advantages of this type of motors include:

- Simple design and high durability

- Low maintenance cost

- Relatively low and affordable price

- Easy and complete connection to the power source

The design of AC electric motors is much easier than DC motors and there are specific types for every application. AC electric motors are divided into two groups.

1. Synchronous AC electric motor:

This type is used in factories and for correcting power factor. In this case, a synchronous bar will not be placed on the electric motor shaft. Also, the fixed motor speed in synchronous type makes it suitable for equipment such as electric clocks. Some advantages of AC synchronous electric motors include:

- Not sensitive to voltage fluctuations

- Has good efficiency

- Has a suitable power factor and is adjustable.

2. Asynchronous AC electric motor:

This type is divided into squirrel-cage and wound rotor. In the squirrel-cage type, the rotor bars are slanted to prevent shaking and locking during motor start-up. Some advantages of the squirrel-cage model include:

- Simple design and affordable price

- Constant motor speed at different loads

- Higher power factor compared to the wound rotor type

AC asynchronous electric motors also wind the rotor with a wound rotor to adjust the current flow from the motor by increasing or decreasing the rotor resistance. Advantages of this type include:

– Motor heat occurs outside the stator.

– It has the ability to receive consecutive starts under load.

– Current in the motor start-up phase is adjustable.

What points should be considered in choosing an electric motor?

Speed and horsepower: Electric motors differ in terms of power and speed. For example, fractional horsepower motors range from 1 PH to 1/20 PH, while large motors have a power range of 100 PH to 50,000 PH.

Motor frame: Remember that the size of the frame does not indicate the performance or power of the motor. Electrical manufacturers design these frames according to the size of the installation.

Voltage: Note that the standard frequency in electric motors is 60 Hz.

Also, the healthy appearance and attention to the year of manufacture, as well as the amount of noise that the electric motor produces during operation, should be examined and given attention.

What is industrial Automation?

Frequently Asked Questions:

What are the types of Siemens electric motors?

Siemens Industrial Automation, one of the most reliable brands, supplies all types of DC, single-phase and three-phase. For more information please contact us on What’sApp.